Broaching on a Lathe or Machining Centre - Tel - 01204 523429 (UK)

ฝัง

- เผยแพร่เมื่อ 2 พ.ย. 2010

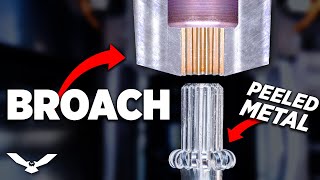

- Machine Tool Supplies Ltd are the UK and Ireland agents for Italian company Brighetti.

Brighetti manufacture a range of Broaching Tools and Broaching Holders thant fit on a broad range of Machine Tools - CNC Lathes, Machining Centres, Drills, Milling Machines ect.

The Broacher can produce Hexagonal, Square and Torx Shaped Holes. External Broaches are also available. Special Broaching Tools can be manufactured to your requirments.

Broaching Tools can be coated with the following coatings - TiN, TicN and INOX PLUS.

Please contact us with your requirments. you can visit our website to view our standard Broaching Tools and Broaching Holders. www.mtsdriventools.co.uk - วิทยาศาสตร์และเทคโนโลยี

I am absolutely amazed!

Brighetti and its partners should be proud, and rightfully so.

Thank you.

Nice tools will research, thank you for this video it is going to make our project much easier to make. Lance & Patrick.

Amazing tool. Thanks for posting.

crazy, coming from a spline grinder, I like the wobbly concept

Good Question!! The Broach does oscillate (wobbles), some people call it Wobble Broaching. The Broach is also set at a 1° Angle in the Broach Holder.

I think when the broach is spun, it tilts slightly toward each point of the hexagon in sequence. So it basically plunges the broaching tool into the part by gradually cutting each point.

This method of broaching has been around for a long time. I was amazed when I first saw this type of broach in action 40 + years ago. We have used a Slater broach to broach tens of thousands of internal gears in aluminum and brass. It works the same way. Do you sell custom shapes for your broaching tool. Your video is very well done. Thank you

This is ingenious!

So, it's basically a rotating chisel? Kinda neat :)

Finishing of your tools and holder is great.

@MrBurnTec Because the movement of the wobbling is what allows the broach to do its thing, this is especially visible in the second demonstration

That does occur when broaching through holes. A staggered progression often from a round, through square and finally to hex form in the one cutter.

@MrBurnTec i'm not a machinist, but I think that kind of operation would require heating and a heavy press. This method eliminates the nead for annealing the finished piece and saves shop space since you don't need a press.

@TorqueRider2000

It depends on what you want to broach? and what machine you want to use the broaching system on?

@MrBurnTec press shaping metal takes a lot more force than a lathe is capable of. the rocking motion of this tool "cuts" the shape. pressing also requires high heat... which alters the strength and flexibility of the metal, requiring heat treatment and annealing to correct after the shaping process. the rotation of the lathe causes this tool to rock its cutting edge into the different faces of the work piece, doing a little bit of the cut at a time.

In the lathe hex-broaching application, what is the purpose of the rotation? Does the broach mechanism oscillate internally as in the vertical mill application?

Where can I get a broaching table converted from metric to standard? I often broach, attempting to duplicate what is suppose created by knurling, I don't have enough tool positions to knurl on the backside but can broach. However, I cannot hold the same tolerances as the form tool the knurl holds and have to often have the print dimensions opened up. Will these broaches cut to the same tolerances as a knurl will form?

wow that is amazing

@MrBurnTec yes... part of the tool spins, the other remains stationary... that's how they get it to oscillate (there's a cam on the inside). watch the tool spinning up to speed at 0:24 and you can see the oscillation.

Wow that's awesome

@MrBurnTec

You can use the broaches on a press. but i would not advise using the Lathe or Mill as a press.

That is bananas man! Bananas!

because the spindle may not be lockable (no C axis) so you need a constant for the broach to work....i guess

Thank you 👌

12.10mm gives you information about the precision of the measurement in question. Due to the practical limitations of any manufacturing process, nothing is ever EXACTLY the size it says. The trailing zero lets you know the size is actually somewhere between 12.095mm and 12.104999...mm. This is fundamental to science and engineering.

John H who gives a flying fuck?go argue with your wife not someone taking time to make a video you lonely fuck

what is the price on a set of these broaches lets say square hexagonal torx polygonal broaches of all sizes small to big and the holder or holders if there are more of them with morse taper ?

Yeah they are Bloody Expensive, BUT, having looked at the website they do give you the option to just rent one, for short runs or one off productions, couldn't find a price for this, but i should imagine that it would be preferable to the high purchase price.

Nice tool though!

12.10mm? you mean 13mm right?

Could this do a 28mm square broach through 1 3/8 thick?

Neat!

Depois da broca que abre furo quadrado, isto é muito interessante.

how much do the two broaches in this video cost ?

What is Twelve.Ten?!

@jmurockstar ahh but it say that there both spinning at the same speed

Where could I get It sir?

@jmurockstar couldnt you just press it in with the machine with out turning

12.10 mm. The zero represents a level of precision of 0.01 mm +/- 0.005 mm.

What kind of positional accuracy do you get with the internal and external broaching (what kind of runout)? What kind of tolerances for the shape on the external broaching?

You would just mill it if it was external

Owen White You would if you had a "C axis & Live Tools". Thats if you producing the job on a Lathe!

Owen White Not always possible. I want to do this on a milling machine to make small gears. It's impossible to mill those with anything larger than a 1/64" endmill for finishing passes. Ideally I would just use a hob, but I can't.

Not to mention that corners on an internal hexagon can't really be milled.

@MrRaajArora you have machines in india?

Dear all. Where can I buy it in Brazil? If you do not have representation in Brazil, what other option to buy it? Thanks Aurelio Palma - Sao Paulo-Brazil

The rotation is used to oscillate the cutter... apparently...

Hi Amol,

Yes you can fit the Broaching Head to a CNC lathe, we can offer the Broaching Head on various shanks. Please see our website

1mm-35mm A/F can be maintained depending on Material.

You can broach Brass/Aluminium/Plastic ect..... Steels and some Stainless Steels.

If you require any further info please contact me

Cheers

Nick

@ogenmatic yep he even says as much in the video

True, but that's not what I was pointing out. He said "Twelve point TEN", it's not ten, it's one-oh, or one-zero.

So.... why spin at all, then stop when the tool comes in contact with the stock?! What am I missing here?

The holder is eccentrically loaded to vibrate the cutting tool and cuts the work piece in tiny amounts, thus giving a controled cut with lower broaching pressure.

I see that now - not sure why I didn't see this when I first saw the video. Thank you for commenting.

Our Broaching Heads range from £280-£650. Internal broaches range from £26-£75

The first demo on the Video, the head is approx £400 abd Broach £36.

As for External Broaching most are made as specials.

many thanks

The tool is at a slight angle

Wow!

from where i can get tht tool in india...

Evviva il genio italiano.

why not just press straight in with out spinning if there going the same speed

Can a manual lathe capable of holding a 2m workpiece give a tolerance of 0.01mm?

No. You would need to grind to get that kind of accuracy.

tubester4567

Actually I was not clear enough in my query. I have a 2.192 meter steel rod of 28.5mm diameter. My application requires a groove to be machined at some distance x from each end. The dimensions of the groove are 2.15mm wide and 0.7mm deep. This groove would be used to seat a snap ring. So I meant to ask, can a manual lathe machine a groove of the said dimensions + - 0.01mm?

Sandarpan Oh I see.....Yes, you can do that. You can either poke the rod through the chuck and leave the rest hanging out the back of the lathe (with a stand but be careful) or set it up with the tailstock if the lathe is long enough. (but you would need to setup the centre steady because the bar is so long it will flex/vibrate in the middle without the centre steady), but should be easy enough, keep the rpm's low. You can use a parting tool for the groove or just grind up a cutter by hand on the bench grinder. Your 0.01mm tolerance is a terribly tight tolerance for a snap ring but you can do it. Are you sure you don't mean 0.1mm? 0.1mm is equal to 4 thou, 0.01mm is equal to 1 thou. That's tiny. Anyway if you use the markings on the lathe (or the digital readout) you should get very close. I would probably just grind the parting tool to the right thickness you want (2,15mm) then after finding x wind in until it just touches the rod, then wind in 0.7mm. Should be very close. Certainly close enough for a snap ring.

do we need to have c axis in our cnc?

No

Good

twelve point one billion! because I'm megalomaniacal.

I am guessing he might be an engineer and just wants to demonstrate that the accuracy is to two decimal places not just one.

What is the benefit of the lathe rotating?

Oliver Masters I think it's just a result of the design, that is, using the axial component of the wobbling motion to do the cutting. Perhaps you can reach a higher cutting speed with rotational motion than normal broaching (purely translational motion) would allow?

@ogenmatic I was wondering the same thing.

Why that happened? The cutting tool and workpiece rotates in same direction....😂😂😂

Neither am I. Im British, I work for an Italian company.

Tonnes of force required. The larger the job, the force required goes through the roof.

Man, I bet those things cost like 10 bucks.

Can you give me the contact to source in India...

@MrRaajArora

You can order direct from us, please let mw know which tools your are interested in.

Many thanks

Nick Greenhalgh do you use any type of coolant or lubrication when broaching hard materials

👍

Then the correct term would be twelve point one zero.

Twelve point ten is completely meaningless. Would you say twelve point one hundred too?

@oli696969

Many thanks!!

SOMEONE PLZ TELL ME HOW I GOT HERE FROM SEANANNERS :/

Oh~!! This is Broaching...I have been misunderstanding...before..+_+;

Oh, I get it. I just don't see that it matters AT ALL. Whereas, not understanding numeric precision and tolerances DOES matter a great deal. I pity your supposed students.

significant figures anyone???

Hmm, I stopped watching at 1:06 ...twelve point TEN?!

Lol. Twelve point ten!

They're not American, they have different customs.

Галимая реклама

I'm guessing the narrator isn't an engineer - it's not "twelve point ten" but "twelve point one". Still, pretty nice, but I bet way out of the price range of a home hobbyist/machinist.

Then say twelve point one zero.

Twelve point ten is never ever correct. you might as well say twelve point 100,OR twelve point one million.

Really?

Math is universal.....

It is Never ok to say "twelve point ten".... EVER.

No. This is NOT the case in Engineering and Science.

12.10, is pronounced Twelve point one, or even (if you want to show resolution or precision of the measurement) Twelve point one Zero. Never, Ever , EVER Twelve point Ten. And as for your numbers, where the hell did you get 12.104999? did you mean 12.104? you've just argued the convention for two decimal places, then tried using a figure of SIX decimal places to prove your already invalid point. Did I read your post incorrectly?

No need to "educate myself". I teach Mechanical Engineering, you are missing my point, regardless of what you say about tolerances( I also teach that as a separate module and have no space here to begin showing you where your you've gone wrong), it is NEVER OK to say twelve point TEN. that's as bad as saying even twelve point one hundred. Its ALWAYS twelve point one zero, or twelve point one zero zero. (depending on the decimal places your want to work to. How are you not getting this?

My point is that twelve point ten IS meaningless. So is twelve point one hundred, twelve point thousand... Its BASIC maths. If you dont understand this, you should be not be in a toolshop.

Sorry, but I want to slap the narrator...