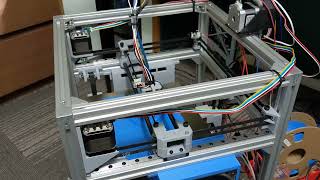

Jubilee CAD File Release and Toolchanging Update

ฝัง

- เผยแพร่เมื่อ 25 ต.ค. 2019

- Jubilee's files are in the wild!

github.com/machineagency/jubi...

I break down the details on:

* Open Source Documentation

* Handling Tool-changes in Slicers

* Maintenance

* Discord

Thanks for all the kind words and support so far. May this project serve as a reference for your own toolchanging adventures.

Finally, I apologize for speaking in sentence fragments ;) - วิทยาศาสตร์และเทคโนโลยี

this design need much more publicity, awesom man keep it up

Thanks; please spread the love!

Yeah- How did I not know about this... I hope this is at MRRF this year!

@@POOFjunior if someone wants to do a project about this printer, where can i find some information, description, like patent informations

@@OWNEDGAMINGwasd I think the best place to start is the wiki at jubilee3d.com

I really want to start building one of these for my own. Your work that you have done so far is amazing and everything is designed so well. After looking through your GitHub page I was sold in the level of details and the entire write you have made. Amazing job 👍

I'm currently compiling the specs I want for a hypercube core xy, and this has piqued my interest! thanks for posting

My tool changer is about 70% done. I have adapted your work here to my existing Core XY machine with some tweaking to some of the models to get them to work on my machine but very happy so far. Just waiting on my Duex5 then I can start fine tuning the motion to tool changing. Excellent work Joshua!!

Wow that looks great! I don’t know when but thanks to you my Railcore will definitely be dual extrusion!

Thank you for your work and videos. I'm in the process of building a railcore at the moment, although it may morph! I do have some of your parts on the way. Thank you again! x

Thank you Joshua for your contributions to the 3D printing community. This is awesome work.

🎖️ Absolutely love it!! I can't wait to get into toolchanging, myself.

I was thinking about adding something new to my Pro 3D V-King and a tool changer is just the ticket, thanks for the inspiration, Joshua!

Looking through the chat I realised I have been here before, I never built a Hypercube, I built the V-King

Fantastic work and great community spirit! Thanks for sharing!

Looks amazing, great job man!

Looking awesome. My next printer will probably include some of this

Superb machine, thanks for your contribution to the community!

Very well done, Thank you for sharing your knowledge and time with us!

Your really everywhere! Greetings from the chickencoop ;D

i cant stop looking this video... i think i watch this 2-3 times every week since release)

Love it so much. Slowly getting there with my toolhanger. It's amazing how far you have come since #mrrf. Hopefully we will see each other again and maybe see this masterpiece in person. Thanks for the effort!

Man, this is awesome, you're awesome, keep it up.

Awesome! It been great watching your designs come to life, just wish I had the time to bring mine to life lol too lol.

Was just lamenting how I could not find all the features I wanted in a standard machine. Stumbled across this on TH-cam and now I have a whole other avenue to explore.

Absolutely incredible project. Need some of the larger 3D printer channels to get into this to give it the visibility it deserves.

Great project. This is more like what I hoped the E3D version would be but theirs is crazy expensive. I will define taking a good look through the details and seriously consider building one.

Very cool, will definitley build on!

Awesome work Josh!

I was searching for a kinematic coupling for a 3D printer tool changer and noticed your youtube channel. First impression: Here we go again, a hobbyist who thinks he can build a 3D printer using 3D printed parts and make a reliable tool changer at the same time.

HOW I WAS WRONG ...

This is an excellent design, very well documented and looking at all available documentation and "source code" I fell in love with this in 10 minutes 😁

I have parts waiting to build a new 3D printer for almost half a year (build size 50x50x50 cm) but have not started because I was not too happy with my tool-changer design. I immediately started printing your parts for the tool changed and I might upscale most of the design for my own printer.

Much appreciated! You're also most welcome to join the crew on Discord to shop around ideas of your bigger setup!

Saw this on Hackaday. Freaking amazing.

Nice work. I've seen a few good toolchanging designs lately. This looks like the most promising. A few notes: I believe with a unit similar to a Prusa multi-material system, it would be possible to have more than 2 extruders, on a board like the Duet Wifi. I also think that the best options for printers, that have a good chance of being accepted widely by makers and tinkerers, require the least additional tools to produce. It looks like you've got some custom engineering in there, to improve the performance of the printer, but I'd argue that some of those choices provide marginal gains, in trade for substantial barriers to entry. But that's just my opinion.

I know this is an old comment, but Jubilee isn't limited to two tools, or even just extruders. You can have as many tools as you have X-axis space to park them. Your assessment of the "custom engineering" on his printer is silly. It's a pretty basic CoreXY with tramming capability, and a novel tool-changer that's similar to E3D's much more expensive option.

Prusa's MMS unfortunately can not get away from purge blocks in it's current state. It is the number one reason I haven't purchased one. This system has a purge bucket but it's just to make sure the nozzle is full before it starts printing. The only negative with this system is that you have to have x-y motion capabilities to pick up the tool, which means it can't convert a bed-slinger, but that's where IDEX conversions make sense so that you can at least get two colors.

This system, with the addition of an indexing gantry, could conceivably have no limit to the number of colors or materials in a print.

omg thank you so much for this !!

Good job, thanks for this awesome channel!

Joshua, let me keep it straight... You are an absolute legend! Tool changing for the masses.

P.S. are you happy with an amount of deflection in the rails/extrusion or you would size up in the next iteration?

So far, I'm pretty happy with the XY size. On a future iteration I might add about 20ish mm in X and Y for a teeny bit more tool space. I don't think this machine scales to something like 600x600, though. At that point, the carbon fiber crossbar may warp non-negligibly with changes in heat.

@@POOFjunior Oh, I meant, is it rigid enough at the current size?

@@yura979 yes it is, but I haven't pushed it to extreme speeds yet. I need better cooling and a better extruder.

looks very nice and saves filament. Gr8 work m8.

So excited to finally see it all together! Would it be wrong to use the E3d TC to make a Jubilee (great name my the way)? Is it possible to add a tool changing counter into the firmware? Prusa's got some interesting memory features, but it's running a different platform. Hopefully I'll have one together before MRRF. Thank you for the drive and passion you have for additive mamufacturing.

Ohh, I"ll look into an odometer. That would be a great addition to get exact numbers on changes.

Nothing wrong with using E3D hardware, although this machine will lock E3D plates, so don't feel like you must to make use of their great tool line.

Stunning. 😎

Great design Joshua! I'm planning to adapt it to local materials, can't import a lot of things in my country. Linear rails in the Z-axis are a must ? Do you think the design will suffer if I replace them with steel smooth rods and quality LM8U ??

Awesome work Joshua, many thanks for share all the information.

I built a coreXY a few years ago and I had many problems when printing circles, for some reason I was not able to print them well, they came out a little oval, haven't you had that problem? Thank you.

Hmm, my first guess would be uneven belt tension?

Love your work! Curious have you ever considered an electromagnet for the locking mechanism?

Thanks! I did, but this mechanism is able to hold heavier tools without me worrying them falling out of the coupling (or jiggling) at high accelerations

Looking really great 😎😎🛠

Man, Seattle area houses the coolest printer designers. Johann with the Rostock and Kossel, and now Joshua w/ the Jubilee!

Now THIS is some exciting news. Really impressive build! I don't have the money to fully build this machine, but do have a slightly smaller, half-built CoreYX printer I am currently working on. I am talking MGN12 rails, 2020 extrusion. If I where to adapt this and include it in my more budget-oriented machine, do you have any special suggestions or things I should look out for?

It shouldn't be a problem, but there would be some design effort. I think the main pieces you'd want to adapt would be the carriage, lock actuator, and parking posts.

This is a work of art. I suppose that bed is cast aluminum?

One reason I want to have a two filament printer is to have the water soluble support structures as well as the other material. I would be interested in seeing a video on how well that wold work with your Jubilee.

Same! I'm taking recommendations and pro-tips on soluble supports, but that is an incoming future mission!

Absolute cool

If you want to improve the audio quality in videos like this, you can use Blender (free, open source, modeling software) to separate the audio from the video and insert a separate audio clip

I still really like your build Joshua, hows are the independent zaxis perform? glad to see jubilee surpass 5000+ changes, much of luck for many more!

So far so good! Autotramming is handled by the Duet, so there's no extra work on my part. It's quite satisfying to watch it realign itself.

Hey Joshua great looking printer man. I am still learning about 3D printing but why can't you make it so when changing colors it uses the normally purged material as infill. It is still viable material after all and that way there would be no waste and no purge just wondering if would do able..........Also do you have a link to discord? Thanks for sharing this information

Nice design.

I wonder about converting my dual extruder printer to this tool changer design??? 🤔

Impressive!

Could you take a page from the Chameleon 3D people and mount a physical switch (or two) to remove the need for the Duex5?

nice build

amazing

Hi Joshua, I like your machine very much. I try to make a mixture of yours with HevORT and E3D machine

How did you make all those metal parts, like the mounts for the belt pulleys? I built a Hypercube myself but want to improve it.

Metal parts? Those are actually off-the-shelf parts called standoffs. You can get them from McMaster-Carr for cheap! Check out the shopping list for more details.

docs.google.com/spreadsheets/d/1gq5yLxlfPtb3yrGsuXR_ZLhAFGB77CzGvfcWYyYIvT4/edit#gid=0

Awesome :D

i wanna try to see if i can only get that kind of tool changing parts to my own printer! i use magnets for now :3

cool project! I first thought you would use this for PnP, but multi-material printing is nice as well. How is the quality of this project at this point, is it production-ready or still in beta-stage? I'm considering what to build as my first machine.

Many thanks! The project has gone leaps and bounds with some extra community eyes on it. At this point, I'd call it stable in the default configuration (i.e: following the instructions on the wiki to the T), and print quality is excellent (surpasses a Prusa Mk3). There are plenty of folks on Discord experimenting with other configurations (Duet3, Klipper), and with time those too will become more stable.

There are still a few missing bits. Having a stable set of slicer config files would be nice, but it's tricky since settings change per-tool and not everyone is running the default extruder tool. Over time, this will get some more documentation too.

But I'd say there's no better time to get started unless you're specifically after a kit.

@@POOFjunior Better than prusa mk3? Bold claim :) I'm joining the discord. See you there! 👍

This look so nice.... :D

гениально!

Great work overall. Why did you move away from the zesty system?

Oh, I just didnt want to build something that deviated too far from what people were familiar with. The remote cable drive is weird enough. Having a familiar extruder hopefully makes the project seem more approachable

Nooo way!!! That’s dank

Looks like that you are controlling the locking mechanism with a bowden and a motor on the right side of this video. Wouldn't it be possible to controll that mechanism with a small servo directly where the cable is attached? :D Awesome project.

for sure! Thats pretty much how E3D does it for their toolchanging Motion System.

In your estimate, how much money would it take for you to be able to profitably sell this system as a kit? How much would you need to be able to scale it to make it adaptable to current ratrig/voron designs?

My current belief is that tool-changing is the future of multi-material printing. It's the only no-compromise solution when it comes to waste and print quality. E3D's system is pretty robust, but it's all-metal, individually-machined pieces make it prohibitively expensive for most.

This system makes the appropriate compromises in materials and the design is fairly elegant. I would love to be able to just *purchase* the system, because I don't have the time to build it.

Awesome, is it possible to make one with different build volumes than in the bom? Also whats the cost to build the printer with 2 toolheads?

GitHub has a list of approximate cost. github.com/machineagency/jubilee/wiki/Parts-to-Buy

Updating the Z axis is pretty straightforward, but growing the X and Y does involve some substantial design work. So far, the cost is 2K with two tools, although it's possible to drop about $200 if you make extruders from cheaper parts.

BTW, Thanks for linking, Jon Raymond!

Hello I am about to set up a second printer my first being a 3 color extruder 3 to 1 and I really like your version with the tool exchange these in your version that I will do it

I wish I could afford to build one :) I have a hypercube evolution and it's honestly so horrible xD I get inconsisstent layers and I haven't been able to fix it after 2 months of everyday effort (had it for 2 months)

I love prusaslicer btw!

also I wish you showed the print I was really curious to see that one :)

I am doing my best to make dents on the BOM costs to make it more affordable. Yes! I will make an album and post them somewhere...

@@POOFjunior affordable to me is 300-500$ xD I'm sure this costs way more! heck it takes me a lot of time to save the 500$-300$ :P oh well once i get a job and all i probably have more money to spare. I don't really buy clothes or makeup etc so I'll have more money to spare ;3

Pretty cool! Can you add more extruders to have 4 colors?

Aye, there's space for 4, but I havent explored it yet because each extruder is a bit pricey.

where does the noises come from? Is it from the 6 motors, the stepper-controller, or just the fan?

Looks pretty cool. I just wonder why so many printed parts are used? The machine i am designing from scratch only uses 7 printed parts, and the other parts are not custom made parts. Except for them being cut to lenght.

Thanks. theres a few more printed parts to get rid of print overhangs. Rather than print one part with a huge overhang, i split that part into multiple pieces. While there are more pieces, the machine becomes a lot easier to print.

Nice

Now we just need a way to slice models to be different colors

:D very cool!

Beautiful build way more simple then that monstrosity from E3D

You do realize that this is based on E3D's open-source "monstrosity", don't you?

I see very big delay before the carriage will connect the tool. From 0:47 to 0:53 it stands and do nothing. Whole 5 or 6 seconds!!!. If we multiply this time on the quantities of tool changing - this delay very much extends printing time

I like your printer!

At least does not waste filament when changing colors.

First thing i noticed. Brilliant.

I don't know what they were thinking making Duet Wifi not support stealthchop!

Wish you would make the whole guide, instructions, shopping list etc as one download on git instead of a ton of individual downloads. Would be so much easier.

On the landing page of the project tuere is a green button that says "Clone or Download" where you can get a zip.

@@POOFjunior doesn't work for me clicked on clone wiki locally and does nothing. Copied link and opened in New page gives me 404 error on page. And no green clone button. And yes I'm logged in

Looks like youre trying to clone the wiki. You actually want to clone the project.

Use this link:

github.com/machineagency/jubilee

@@POOFjunior thanks that worked.

How much is the printer cost in total? :) just for some reference

What controllboard are you using ?

I'm using a Duet 2 Ethernet and Duex5, but some folks have built up Jubilee with a Duet3 and a few others with Klipper.

github.com/machineagency/jubilee/blob/master/frame/assembly_instructions/wiring/duet2/duet2_frame_wiring.pdf

What's the build volume

it's 300x300x190mm. I made a specs doc with more details if youre curious!

github.com/machineagency/jubilee/wiki/Feature-Breakdown

thank you, fantastic 3d printer

You figure out the air/ fan yet

Still working on it. For PLA, part cooling is definitely my limiting factor right now. For low detail parts, my top speeds are around 120mm/sec for inner perimeters, 78 for external perimeters, 180 for infill, and 333 for travel moves, which is respectable for low detail parts. For detailed parts, I cut these down to 1/3 for perimeters. Pushing past that, cooling starts starts to become an issue as the part can't cool fast enough before the next layer is deposited. I'd say that that's a respectable start though.

@@POOFjunior can't wait to see more love when people build shit and actually show/ talk through problems etc and document like you have keep it up

I'm too broke for this xD

q

I’m disappointed. I thought you’re releasing the 3D printed tank or helicopter