Over-Engineered Pen Holder?

ฝัง

- เผยแพร่เมื่อ 14 พ.ค. 2024

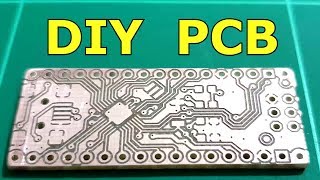

- Another pen holder for the HyperCube CNC, this time with 1-axis of freedom for varying Z heights.

💚 Enjoy my videos? Show your support on Patreon! / tech2c

Reprap Wiki - How To PCB from Eagle:

►reprap.org/wiki/Howto_PCB_from...

PCB stuffs:

►www.banggood.com/search/pcb-c...

Download the Pen Holder:

►www.thingiverse.com/thing:245...

Download the HyperCube 3D Printer from Thingiverse:

►www.thingiverse.com/thing:1752766

Buy cheap 3D Printer kits and parts from Banggood:

►goo.gl/bFyz5H

Amazon 3D Printers and Parts:

►amzn.to/2qdTebt - วิทยาศาสตร์และเทคโนโลยี

I had never thought of producing PCBs like this, and I love the fact that you are finding more and more uses for the same, base frame, and still working so hard on the Hypercube as a whole. Its nearly a year since you first showed it running! Happy (almost) Birthday Hypercube!

One year later this post is still pretty instructive. Thank you so much for sharing your valuable experience.

Those videos are getting more and more higher in quality, awesome!!

I’ve just made this and it works so well. Thanks for your great design.

A great reuse of surplus of parts and a good design. That's what I like most. Bravo.

Man Ive been dying to make a blotter from my 3d printer. Love the idea of the rails, brilliant, keep making cool stuff.

Simple and elegant. Love the design.

Very interesting, I can't wait to see what you do next :-)

Very nice, productive and worth to see video. Thanks for your effort.

eurgh this is so cool. i have no use for it, but watching it draw out the PCB traces was so cool

The 'imprint' was just some cleaning of the copper surface done by the solvent that the pen has in it.

Basically it the cleaner bits of copper.

16:23 the felt marker polished the copper

That makes sense, thanks.

or removed the photo-sensitive layer

deadall127 no photo sensetive layer on that pcb..

The ink protected the copper from oxidation. The color difference is from a minute difference in an oxide layer. Try drawing half a schematic, wait an hour, and draw the second half. Clean off the ink and compare the traces.

that makes sense too :)

btw, if you want to make a real pcb with this cnc+pen, you should use a plate covered with a photo sensitive layer, then expose it to UV light, then disolve the copper and finally clean the board and make the holes :3

OR simply replace the pen with a drill XD

Would love to see an attachment for cutting too. Like vinyl cutting etc. Other ideas include a paste extruder and pick and place attachments. Great videos!

I haven't etched in over two decades ... this is inspiring cheers.

plasticmodeling and pcb building was my life in early 90's , cheers :)

It is cool some times you may want to make your own circuits. For me I have about 10 I want to make. Some might be over and over.

These videos always impress.

phenomenal DIY work.

I was thinking, "fuck, this could be really useful!" And then I realized that I already owned a laser printer

especially when you put the locking bolts on the non moving part seems a no brainer to have the moving parts have the lock bolts on them

😄

Turning a 3d printer into a 2d printer! Wait...

great design and application :)

Amazing, thank you for sharing!

Two minutes in, my feeling is rails on the first one or another clamp at 90° on the second. I love how your solution took the both of best worlds, it's beautifully silly.

Awesome! Would love to see a recreated version customized for the Prusa Mini

Next video on tech2c... Hypercube cnc milling machine for pcb making?!?!? :D

Btw. LOVE the hypercube design!! Just started building one too!! Just waiting for the rest of the parts to arrive, and printing one of the last parts out on my fabrikator mini at the moment! :)

It looks like a breakout board with support circuitry for a Pic16F84 Micro-controller (Microchip). Cool Idea actually.

Perfect design.

I know what we used when I was working with cnc the pen had a secondary spring and the casing held them and the pen cartridge so the pen casing was held with a set screw still allowing for odd surfaces

could have put a pair of springs above the bearings, as well. Just some light compression force. More prior planning, but no worries about the rubber band breaking or anything.

In a word ... Genius.

Awesome video!!

love it man Great idea haha

Use two of the C clamp styled ones in the format of the double screw clamp version, but offset them from each other so they take up the play from each other.

You should make a version that accepts the standard brass bushings as well!

Hi, how do you remove the linear bearing from a pillow block? i have some that are really stuck

In the case of the retracting ball pen. A quick and dirty hack is to put the spring on the other side of the stop on the ink tube.

There are LM5UU and 5mm rods available quite cheap, most probably will work just the same while reducing weight and cost.

I find it perplexing when someone's content is way better than the topic chosen.

Hi, nice video again.

At the moment I'm using the toner transfer method to develop pcb's. But this technique seems much cleaner. The thing I noticed is that all video's using the direct ink to pcb method create pretty coarse traces. It would be interesting to see if it's possible to create for example 0.5 pitch traces with a finer marker.

Maybe it's an idea to use a coarse pen like the 0.6 for copper pours and a finer one for the traces. Maybe this needs a dual pen setup, if replacing the pen mid process would mess up the alignment.

Excellent!

Hi thanks for sharing your work i love whate you do , i have a question about a GRBL ; is it possible to change or add somme subroutines to that code , for example reading a sensor value and send it back to the UGS, thanks in advance.

the version with the screws work, by using a square opening istead of a round one. the sqare is split along its diagonal

thanks , that is great

Is the 3D pen holder (using two8mm shafts) available, I don’t have a 3D printer but I would like to build the pen holder?

Thanks

16:21 I think it's just polished from the friction of the pen tip.

Great idea good for pcb

perfect for writing christmas cards

It would be interesting if you created a carriage mount that used neodymium magnets instead of screws for quick replacement

Awesome!

did you finish the PCB? I'm really interested to see the rest of the process.

thanks I found this really usefull. I recently bought have stepcraft cnc, and can modify this concept to fit my machine (in due time when my skill levels rise). I'm not familiar with the Hypercube. I was surprised that you didn't talk about drilling NC files. To my way of thinking the real benefit of using cnc to make home made pcb is that you can quickly and accurately drill all those holes.trying to get an idea of the process. Wondering if you would drill the holes first and then, use one of the holes as a registration point for plotting pen..so that everything aligns??

Have you etched a pcb using this method? How it turned out? I want to get into etching but don't own a 3d printer and I'm thinking to build a simple 2d plotter.

he be rollin down the street

he be rollin to the beat

the clean areas where probably from the Acid in the pens ink cleaning off the oxidation on the surface

I always love these videos. What do you use to design your parts? Software I mean. The printed samples are excellent in your videos!

Up until recently I was using Cubify Design, but here I'm using Fusion360.

Awesome stuff! Is it possible I can send you a private message too? I have a weird problem of with my 3D printer with regards to my Z off-set? Also, will be building my own HyperCube soon, can't wait! :)

It's an impressive pen holder.

Is it possible to order the finished linear bearing pen holder

its a good thing we invented the printer....

I wonder if one could use kicad as source for pcb to be cnverted..

If you enjoyed this video !!

are you series ..... absolutely i have enjoyed this video also i like your clear explanation

Thank you for your time and keep updating the cube 😉😎😎

I'm intrigued by the scale factor for "to mm" in the HPGL to G code converter.

HPGL units are usually thou, and there are 39.37 thou/mm, not 40.2? (1000thou / 25.4mm)

Is this to compensate for a subtle scaling factor in the 3d printer?

Cool design but u really should think about some spring for example: bed spring or something similiar with less tension on other side.

What program are you using for plotting with the pen on you printer?

Bom dia, tenho uma maquina da eleksMaker Draw none, ela desenha com a caneta só que ela tem um problema (7:00) não mexe essa palheta branca para levanta a caneta, como posso resolver isso?

this is the correct amount of engineering.

So the material used for these homemade PCBs, am I correct in thinking that it's a nonconductive material with a conductive veneer? And that the veneer is dissolved using some chemical, leaving only what's under the ink as the circuit?

i just shortened the the core of the pen and put the spring inside the pen on top so it can retract on pressure with very minimal wiggle :) this one is definitely over-engineered :)

why the fck did i watch this entire video

I used duct tape...

Are you MacGyver :P

Tech2C or a mythbuster?

i used my hand

Jacob Flink q

...and I used the Force...

the example circuit that you used was Designed for a 2-sided pcb

You see a pen holder. I see a projectile launcher

When I press x plus, plotter moves diagonally. Same for y axis. On pressing diagonal arrows, it moves in one direction.

Which software you use? I built the openbuild Acro CNC and I removed the laser and I will install your pen holder, I like the idea when the pen hits the paper I have _on my case_ 2 springs, anyway I tried a few software and so far none of them captivate me

Hi guys, I am new for 3d printer setting. While using this pen holder, I can not set Z,. Pen goes way down and damaging bed, can I get help here,, please

When I was a kid we had write 100 times of so same stuff as punishment. This will help so many kids with that!

idea: you can add small servo to lift pen holder up instead of using Z axis. With small circuit you can use any digital pin and replace all Z lines in g-code...or if your drivers take STEP and DIR pulses on input, then (with a little better circuit) it should be simple to connect servo to board instead of Z axis driver.

But I guess people won't use this so often and seriously, so waiting some extra time for Z axis movement won't be that big problem :)

Nice video

Awesome!!

That's some great work! But it needs some LED lights lol :)

Do you prefer Etch vs Engrave cutting the board away? All though both effective methods I personally thing engrave looks better and no need for mixing a solution

This is a nice design for holding the pen.

I do not know if you are looking for other ideas... If you are then may I suggest a solder paste dispenser attachment? For a hint, look at Dave's (not going to mention his TH-cam channel out of politeness but it's that self-described crazy Aussie bloke) latest unboxing video where he got an automated SMD dispensing pen. An adapter for that on the Hypercube would allow the finished PCB to go back on the printer for placing the solder; this is an alternate to using a paste mask.

AFAIK, I have not seen a 3D printer being used to dispense paste before.

Oh, and the pen can also be used as a pick-n-place head, for placing SMT parts... but this requires a lot more gear to go onto the 3D printer.

Just putting it out there as possible future extensions on the printer.

Cheers,

- Eddy

can i use Kicad instead of eagle? its a free open source software for PCB design. Thanks for the very nice video!

Did you check out the magnetic tool changer for Ultimaker? You could apply a similar idea to Hypercube for dual extrusion and tools.

That is a very smart design.

Might be less weight on the moving part if the 8mm rods moved and the linear bearings were clamped to the mount.

Purely genius. Can I use the same principle for a Micro Electric Hand Drill for PCBs? Rotating tool anyone?

The board is just a simple dev board to make it easy to use a pic16f84a. The 16f84a is an older flash based pic chip. Microchip has a huge number of devices in their lineup.

Ok thank you.

This is a lovely design. I have just purchased a little desktop CNC and, based on your design, I have ordered the linear bearings and rods from China. Now, I have a couple of months before they arrive, to draw up the holder so it all fits my gear. Since I'm a machinist, I may make the rod mountings slightly more skookum on a metal lathe. There is NO such thing as over-engineered! :-)

Would you, based on your "over engineered design", build a heavy duty CNC plotter, with very high accuracy, capable of drawing on A0 format? What would be the price of it? With stepper motors and Raspberry pi 5

you need the locking mechanism placed on a rail that moves in the direction you require

Did you use your latest 3D-printer to print these outstandingly looking details?

Did you do acetone vapour smoothing?

All printed on the HyperCube. Link is in the description.

These plastic parts are PLA printed at 0.2mm.

Wont be easier to use standard garber files then go through flatcam to get gcode???

awesome design! What app do you use for designing? --> just seen it in another video - it's Fusion 360 :-)

..whats the purpose of the kork mat below the bed?

Its to keep the heat in. Some printers have a heatbed which doesnt get hot enough to properly print abs. Cork is a easy and cheap solution to that.

Thanks Marcus - makes totally sense. It might also avoid that frame parts below the bed get warm.

Great video. However all those unnecessary pen lifts would annoy me. i wonder if there's a way to filter them out of final G code

You are not alone. Yes there are tools for that like xyzbots.com/gcode-optimizer/ but this tool assumes G0 motion in between G1 drawing sections, plus I am not sure it can remove unneeded up and downs.

I agree the code could be more efficient, but the entire drawing took 4 minutes, so saving an extra minute or 2 really isn't a big deal.

Yep; learn a bit of G-code (it really isn't that hard), then use a regular expression search-and-replace in your text editor. Done like dinner.

I wish they had multicolor pen for the xy plotters

Why dont you put springs over the two rods?

what kind of surface finish are you doing on your prints? or is this just a f*** good calibrated one?

It's just a good printer. Tinkercave has a video showing good print quality that several of us in the HyperCube community are getting, and there are lots of nice example prints on the Facebook group.

how about a iris-style variable width guide bearing? ;D

Hope you plan to make a milling attachment.

Maybe... (yep)

Wrap some tape around the thinner pens.

Could you link to the pen you used - im having difficulty finding them here in denmark... perhaps an amazon link?

Staedtler Lumocolor permanent pen 318-3

Thanks

Did you always intend to use the HyperCube for these pen/laser/milling CNC designs you're doing now, or is this a fairly recent idea?

Recent. During the HyperCube build log series I just wanted a better printer. Earlier this year I released a video called "Draw with your 3D Printer!" which is when the CNC idea came about.

Now you need to drill the holes in the board. That's more work than just drawing. You need another quick connect for a Dremel or somesuch.

help me with 2 questions, what printer do you use to get that quality? and, what kind of filament do you use for that piece? thanks

HyperCube 3D Printer. Link is in the description.

eSun PLA+ Grey 1.75mm filament.

thanks

bruh I straight up used a design that was opened and doesn't need to be locked in place, only with a few rubber bands which help it flex , the whole mech is also held in place with rubber bands whcih allow it to move up and down only.