5 Ultra-Insulated Framed Walls

ฝัง

- เผยแพร่เมื่อ 17 พ.ย. 2024

- Let's talk wall assemblies. Bomber wall options to frame a REALLY good wall with 2x4-6-8’s and some thick insulation. A home built with any of these 5 walls will be a comfortable, durable, efficient house that will last for generations. In this video I’ll run you through all the options, including the Costs!

6. 2x6 w/ zip R-3 (or R-6, R-9, R-12) and batt Rockwool R-23 insulation

Effective R-value of opaque assembly = 22

$3.62 per sqft

7. 2x6 w/ plywood, Delta Vent SA, Rockwool Exterior comfortboard 80 (1.5”), and batt Rockwool R-23 insulation

Effective R-value of opaque assembly = 25

$5.82 per sqft - (60% more than previous assembly)

8. 2x4 w/zip sheathing, Atlas energy guard 2” polyiso (R-13), and batt rockwool R-15

Effective R-value of opaque assembly = 27

$ 4.05 per sqft - (30% less than previous assembly)

9. 2x8 w/ zip R-6 (or R-6, R-9, R-12) and batt Rockwool R-30 insulation

Effective R-value of opaque assembly = 30

$4.82 per sqft - (19% more than previous assembly)

10. 2x8 w/ plywood, Prosoco R-guard, 3” of Polyiso (2 @ 1.5”, offset seams), and batt Rockwool R-30 Insulation

Effective R-value of opaque assembly = 45

$7.13 per sqft - (48% more than previous assembly)

R-value (effective vs nominal), pros, cons, price breakdown

Assembly R-value Calculator

Prices only reflect lumber, insulation, WRB, and Sheathing of assemblies from my local lumber yard. Does not include hardware, fasteners, tapes, flashings, labor, etc. Used a 8’ x 8’ wall assembly to calculate.

As you upgrade your wall assembly materials and methods, it is just as important to upgrade any other parts of the assembly that affect the performance such as windows and doors. This is just a look at the framing, sheathing, and WRB assemblies relating to R-values

Opaque

All areas in the building envelope, except fenestration and building service openings such as vents and grilles.

R-value

A measure (h ft2 °F/Btu) of thermal resistance, or how well a material or series of materials resists the flow of heat. The R-value is the reciprocal of the U-factor.

Effective vs nominal r-value

Nominal R-value took into account the thermal resistance of the insulation layer only, typically batt insulation placed between the studs. Effective R-value, on the other hand, takes into account the cumulative value of thermal resistance for all materials within the assembly.

Renderings done by:

Lou Varni - @Lvarni

Follow Matt on Instagram! / risingerbuild

or Twitter / mattrisinger

Huge thanks to our Show sponsors Polywall, Huber, Dorken Delta, Prosoco, Rockwool & Viewrail for helping to make these videos possible! These are all trusted companies that Matt has worked with for years and trusts their products in the homes he builds. We would highly encourage you to check out their websites for more info.

www.Poly-Wall.com

www.Dorken.com

www.Huberwood.com

www.Prosoco.com

www.Viewrail.com

www.Rockwool.com

Matt,

You are costing me a lot of money. My home, which my wife and I love, was built in 1961. My utility cost is crazy high and I am repairing on stripping my home down to the studs from the outside, using new insulation between the studs, adding zip sheathing and an additional 2” outside of that then furring then siding.

I have built only 16 homes in my life, thought I knew it all, it through watching your content and studying the building science behind your thoughts I didn’t know much.

Thanks for the knowledge and keep it coming.

I pulled all the drywall in my house, furred out the 2x4 to 2x6 and used R21 in the walls.. I blew in r60 in the attic and I've reduced my bills by 50%.. best bang for the buck as these ultra expensive assemblies will almost never pay for themselves in energy savings..

Chris that is another good answer but I am already going to pull the cedar siding and replace with half log siding with dovetail corners. That is the main reason for my attack from the outside. Also whoever built this house installed two layers of 5/8 drywall from ceiling and all walls and I do like that.

@@FJB2020 That's been my thinking for a while with old houses. My SO's house has a small (8'x12') sunroom added at the rear quite some time ago. Just paneling inside with vinyl siding. I pulled the paneling off (tossed it!), and pulled all the insulation out, then caulked ALL joins where studs meet the sheathing, so all four corners of each stud box. Put the insulation back and drywalled over it. She used to get tons of stink bugs, now, none. She can keep the door open and it cools just fine now, or heats in the winter (zone 4). Sealing the joins is as important as insulation in my experience. I'm not a builder, but the difference in this job was astounding. Now I want to do that method on all the walls in the house, but she won't let me. :-)

@@johnflannery4815 if you are pulling the siding, then go for it.. in my case I had 3/8" drywall and I was rewiring my home.. I also got a killer deal on 6" cased pella windows (90% off) so I furred out with some ripped 2 by material..

I would love to see some ceiling/roof insulation option done in the same format. Keep up the great work.

And slab insulation too if possible!

Cellulose on the attic floor is the cheapest best way period

blow in insulation in attic is best way. get R60 up their agreed@@justinballard7242

Raised heel trusses. Run exterior insulation past top plate up to overhang.

6. 2x6 w/ zip R-3 (or R-6, R-9, R-12) and batt Rockwool R-23 insulation

* Effective R-value of opaque assembly = 22

* $3.62 per sqft 1:19

7. 2x6 w/ plywood, Delta Vent SA, Rockwool Exterior comfortboard 80 (1.5”), and batt Rockwool R-23 insulation

* Effective R-value of opaque assembly = 25

* $5.82 per sqft - (60% more than previous assembly) 3:35

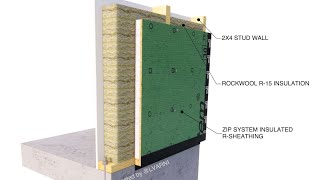

8. 2x4 w/zip sheathing, Atlas energy guard 2” polyiso (R-13), and batt rockwool R-15

* Effective R-value of opaque assembly = 27

* $ 4.05 per sqft - (30% less than previous assembly)

5:53

9. 2x8 w/ zip R-6 (or R-6, R-9, R-12) and batt Rockwool R-30 insulation

* Effective R-value of opaque assembly = 30

* $4.82 per sqft - (19% more than previous assembly)

10:52

10. 2x8 w/ plywood, Prosoco R-guard, 3” of Polyiso (2 @ 1.5”, offset seams), and batt Rockwool R-30 Insulation

* Effective R-value of opaque assembly = 45

* $7.13 per sqft - (48% more than previous assembly) 12:29

I do blower door tests etc on new homes here in Wisconsin and I often see large homes that perform so-so. Not terrible compared to many fast-built tract homes but could be a lot better. My advice to people who have the luxury of planning a home build is to eliminate some square footage and put that savings into performance. Also, simpler designs are easier to make tight and to perform better.

I live in Wisconsin and will be designing a home soon. Do you have a website you can reached at?

Love the info you present! As an HVAC contractor in Forida I agree with you 100%! Keep educating all of us!

Would love to see a double stud wall option

Me too. It’s an option I’m considering.

Me too. ISA architects in Philly designed some double stud walls 24" on center with rock wool that were super insulated and inexpensive. I think the builder was Postgreen, and the framing crew was "Old Glory". Also, how do I find a builder in my area ( Northern NJ, but in general) that has experience with detailing and sealing?

Vapor barrier was on the outside of the inner wall so no penetrations for wiring and plumbing.

I did that in my home theater.. it is great for both thermal and noise comfort and cost the least amount compared to "engineered" assemblies..

I used a double 2x4 stud wall on my house with 2x8 plates, window and door openings. Zip on the exterior. Rockwool the outer stud bays then ran electrical, no drilling, all the wiring was stapled to outer studs. Then insulated the inner stud bays. No slicing batts to tuck around wires and all electrical boxes have insulation behind them. The house is energy efficient and also very quiet.

I was thinking the same. I live in zone 6, so very cold winters are in play for me.

Matt I always enjoy all of your videos, in 2000 I retired as a residential contractor in the Northeast and move to the Florida Keys I constructed my home using ICF and a hip roof ,standing seam roof and close cell foam to the underside, in September 2017 we were hit by hurricane Irma we stayed in the home and had absolutely no issues I videoed some very compelling videos during the hurricane inside the home as well as in the attic showing the benefits of close cell foam as well as ICF Construction. I believe in the cost of ICF Runs somewhere between five and eight dollars per square foot , if you are interested in seeing and or posting some of the video I will be happy to forward it to you thanks again Norm

Cool video. You should also do some alternative wall systems such as double stud, clt with exterior insulation, icf etc. Then maybe another series on foundations and roofs.

Drives me nuts how content is presented for the sponsor benefit. My experience and calcs say the best approach is to do a conventional frame; 2x4 or 2x6, depending on wind loading for your area, then sheathing of choice (ps guys, OSB is not horrendous vs plywood, which has all sorts of QC issues of its own). Then, 100% liquid applied or self-adhered with liquid applied as required (such as outie windows, and bucks fully coated, unlike Matt's own build). And I use Barritech VP liquid applied, from Carlisle, for good reasons. Then, MAX OUT the continuous exterior insulation. It all comes down to the entirety of the delta temp that any part of the assemble, and its insulation materials, are seeing. Once inside the continuous layer, the heavy lifting (thermally speaking) is DONE. And bear in mind that the cost of a rain screen/ furring is ignored in the ZIP R versions shown here, despite being promoted incessantly here as the "right stuff". Can't walk both sides of the street, in my world. And, if one is going to perseverate about the cost of fasteners, keep firmly in mind that Rockwool is a good product, but is about half the R-value of polyiso, per inch. That means you need a LOT thicker blanket and finished wall assembly, for the same thermal performance (hint: look at fastener schedule and costs carefully). Law of Diminishing Returns says put the most you can in the continuous exterior layer, have an awesome air seal, and don't waste time and money on the cavities; FG batts have a better return on money spent. Finally, don't just throw up fuzzy stuff and hope it sticks: do the calcs as to where the dew point falls within the assembly before you set out. Tough to find out 5 years later you are condensing all winter on the inside of the sheathing.

You don't need exterior insulation.

nice post, TY

@@JamesG1126 hey do you mind expanding on that? Thank you

@@hihokie Exterior insulation is very labor intensive to install. You need to have vertical wood strapping covering the entire house and it makes the siding install more labor intensive too. For the minimal R value, I don't think it makes sense in any climate zone 5 or lower. Maybe for the coldest climates.

@@JamesG1126 So how do you build? And how do you restrict to "minimal R-value"? If I restrict any described method to a failure mode, of course it will fail. You seem to be suggesting that BSC are idiots, and the Perfect Wall can't work because of "minimal' R-value. On my jobs, we find the calculations and the performance to be diametrically opposed to your assertions. Per my starting comment, continuous exterior or a hybrid system makes everything within the sheathing totally simple and straightforward, no special care or expense, either materials or labor. Put your money where it does the most good, which is outside the sheathing.Even Matt's darling architect Steve B has said exactly that, in posted interviews (you could look it up). Makes the whole deal with conditioned attics and basements or crawls extremely easy and straightforward as well. And, the whole issue of condensation within the wall cavities goes away completely.

You can continue to build as you do, but I take the long view on cost-benefit and risk-reward analysis. Decades of pushing the envelope got me where I am on this.

Bet you're loving that extra insulation with the rolling blackouts in your area right now. Very smart!

My walls are R80. I live 45 miles in the woods past Glennallen here in Alaska. Winters are -65 to -80 and I am nice and warm all winter long.

I think one thing to consider would be cost per R. While the cost on the last one was over $7 it was about 15 cents per R value. The "cheapest" one ran almost 17 cents. Just something to consider.

Definitely worth considering. If memory serves EPS is usually pretty cheap for the R value, so if you don't care about the fire risk wrapping your house in a thick layer of that with the cheapest structural materials and no insulation in the stud bays would probably be about as cheap per effective R value as you could get.

thats true but at what point is the R value diminishing? i mean if your under water theres no air but if i give you one of those black coffee straws you got some air but your not going to be able to breath. how much better is 30 vs 45? all the passive home people say they can heat there homes with 2 hair dryers but if i have to use 3-4 hair dryers is it really a big deal especially if i spent 10-20 thousand less? R value needs to have more meaning behind it to justify spending that much extra.

@@JareBareXP the point at which you get diminishing returns on adding more insulation depends on the cost of the energy you are using to condition your house, the quality of your air sealing, the cost per square foot of R value for the insulation you are using, and the climate you live in. The sweet spot for lifetime cost usually works out to be pretty close to what most passive house standards recommend (since most passive house standards are designed with the intention of you paying for your energy up front). If you don't plan on owning your house for the next 30 years it might be cheaper for you to use slightly less insulation. It technically is possible to over insulate a house to the point that it reduces comfort, but the amount of insulation needed to over insulate a house is usually about double the amount recommended by most passive house standards.

@Gareth Baus is there a set point? Or a common ground? When they run that door air test it seams great. I'd love to see some studies on "R" values and these door test for homes that prefer similar temperatures and are located in the same city with similar squar footage I'm cerious on the cost to heat or cool there homes does a .3 value astronomically better then a 1.0 obviously there's more to it, considering people maybe open or close the door more then the other person but it will still be a very important value to know. It would be a beautiful study if someone had the resources.

@Gareth Baus thanks for replying to me btw! I'm a bit inexperienced in this stuff let me know if I'm missing a bigger picture. So far it seams like it's comparable to over-clocking a CPU "yes it's better then before but who cares if your getting 2 frames more in minecraft if your already getting 300+." Is what I see. Seams more like a flex

I wish you included the ROI of each assembly using a standard energy cost that we could scale.. It would really help people build cost effective, yet energy efficient homes...

it is not necessarily about ROI , but more about comfort levels. For example my energy bills are pretty low in comparison to my neighbours , but insulation level of my roof assembly is not enough. So every summer it is pretty hot on second floor.

@@Артем-э2г8т then you're not putting your energy costs in the right places because your HVAC should be easily able to cool a tight home

@@alpha.gamma.dingdong i am mostly heating my house. And its pretty comfortable without ac in every room except 2 specific bedrooms upstairs with shitty window placing and poorly instaled insulation.Two other bedrooms upstairs always stays comfortable in summer.

@@Артем-э2г8т so in summer you lose 2 rooms to hell

Too many variables. Climate, defined by heating-degree-days and cooling-degree-days. Cost of energy. Source of energy. How much comfort matters to you. Local labor cost (which changes the total cost). Etc.

Example of source of energy. I've been contemplating super insulating my cabin in the Colorado mountains. If I get my energy use low enough I can switch from delivered propane, to electricity. As the ultimate step, I can make and store my own electricity, which isn't possible with propane. I've come to hate the hassle and expense of propane. As it turns out the largest materials expense is the cost of decent doors and windows.

Great video! I would love to see these framing options with using T-studs!

The renderings really made this video, very impressive.

Thank you for the content. I hope you move beyond the wall sections to show insulating the foundation in cold climates. They will even include buried insulation at an angle sloping away from the foundation to prevent frost and cold from being driven under.

Wondering how much of a change it would have on the R value if I replaced the 2x4 / 2x6 with a T-stud 2x4 / 2x6 ??

Sage Boyette Dunno but I like those T-Studs

Thanks Matt, great info!

In my new house build in Climate Zone 5 close to Pikes Peak in Colorado. Very tight air & moisture control, unvented roof (no penetrations, all vents go through gable ends). Main level is basically a walkout basement with 8” concrete walls. All my insulation is on the inside of the concrete walls. . Walls are R44 total with 7” of foam sheets + 3.5” of Rockwool in the inside stud walls. I learned that the Polyiso yellow foam looses R-value greatly with temperature drop, so in my walls I put 3” of EPS up against the concrete & the 4” Polyiso on the inside, then the 2x4 studs with Rockwool. So the walls are about 20” thick.

James - we are going to be building our new home in the Colorado Springs / Black Forrest area and appreciate the info! I was watching this for cold weather insulation ideas.

@@ClawsonMatt Good luck, my daughter lived in Stetson Hills when the big fires hit. There are many new tract houses (code minimum) being built up in West Black Forrest.

I liked the rockwool R-30, plywood sheet and comfort board face. Great explanation on it all, it answered all my questions on how I intend to proceed with my project.

Hey Matt, just wanted to let you know how much I enjoy your videos. Great topics, and well presented information. Thank you!

Really great. Roof assemblies next? Would really love to see Lou’s detail of your house roof details. The outriggers on that are genius.

Yeah, there is a great deal of emphasis on walls but little on roof or foundation. Is that because the complexity of walls leads to more mistakes and problems, and therefore getting them right is harder?

Genius?? Wow. As a design builder for decades, and having done variations on continuous exterior roof insulation systems for over 40 years, I see that detail as pretty pedestrian at best, mediocre choices of compromises at worst. Last time I did overlay outriggers and stopped the roof foam at the wall line was 20 years ago, and for good reasons. Dr Joe has since published the reasons. In our Colorado climate, insulation all the way out to the sub fascia may not be mandatory, but it is if you want to avoid problems, such as ice damming being made worse. My big issue with Matt's (really Steve B) outriggers is the fussiness and the disruption of the continuous exterior roof insulation. See Dr Joe re: air networking. The reduction in insulation value over the outriggers is also a factor.

We have done similar situations, and here is what I would consider a smarter, more integrated approach to the problem: If 3 1/2" LVL's flat at 24" OC will support the load, then 1 1/2" x 3 1/2" LVL vertical at 48" OC will be even more capable of supporting the load. Since Matt got a deal on LVL and used them for all rafters, it is simple to extend out and cut tails on every other rafter (3 1/2" +/- high). Since Matt is fully on board with liquid applied, that insures a seal of the projecting tails to the ZIP, really no different that around windows, etc. The disruption in the foam is now on the wall, the tiny cross section of the LVL tails. The bridging through that cross section could be reduced by an extra 2" polyiso collar around the tails, hidden in the boxed soffits The heat path is now longer through the tail, from out to in, so the R-value of the LVL tail is therefore increased). A deeper fascia and soffit is a byproduct, which is used to advantage. An LVL sub fascia is now 9" +/- deep, and can cantilever at the rakes to pick up a deep LVL barge rafter, whose top end is supported by a projecting LVL at the ridge. Then a nailer over the rake wall foam, and lookouts tying to the LVL barge rafter. Not hard, we do do this.

As for roof, one approach is to restart the inner sheathing outboard of the wall foam, to support the continuous exterior roof foam all the way to the sub fascia. Now, blocking above the tails, outboard of the walls to support the upper roof sheathing present far less air movement/ thermal issues than does Matt's outriggers.

Great video! I would love to see the exact same presentation but for roofs and/or ceilings. Especially with engineered trusses.

Thanks for simplifying something that can seem complicated on its surface. So many options and decisions, you (with great visuals) did a great job explaining things.

PS, I'm currently replacing sheathing that was water damaged, so thankful it wasn't cardboard.

Something that would be really interesting to see: how investing in insulation reduces your HVAC costs and how quickly it pays for itself in energy savings.

I bet it helps a lot! I just had my very leaky front door replaced and they insulated the voids around the door frame. The front room is no longer 'muggy' and my electric bill dropped almost $50! I've also been able to keep the thermostat at a lower temperature without the HVAC running non-stop. Who knew?

Paying for extra insulation up front might save you a ton of money up front by reducing the size of your HVAC systems. If you are retrofitting, the ROI is likely too long. In that case you are paying extra for comfort

@@sd0753 yeah for new construction I'd really like to see a breakdown on how spending more on insulation and air tightness reduces the cost of the HVAC and then how quickly you recoup the balance of additional expense in energy savings.

Its simple to figure, do a free online manual J calculation, you can vary the levels of insulation which in return will tell you how many BTU a hour the house will take to heat and cool at any temp, then covert BTU to KWh based off the A/C or heat unit you plan to use.

While thats a estimate and will be approx and vary,....you can get it very very close by doing a hourly historical weather chart for a previous month for all 30 days....what was the temp at 8 am for aug 1, 2019, then 9 am, do all 24 hours for all 30 days, total the BTU`s and then apply your selected equipment to figure out resource usage to generate those BTU`s......you can do a daily/weekly/monthly cost for a real month at your location last year or any previous month the data is available for in any area...from florida to alaska.

@@alldecentnamestaken

Like solar? Bahaha. No. YOU won't see an ROI but the next owners will.

Awesome man. My house burned a while ago. Looking forward to working this problem through. Great information Matt! Thank you!!

Just built a 2x8 wall with blown in cellulose and Zip-R 2 1/2 on the outside!!! Thanks for all the advice on building science 👍

Why cellulose vs Rockwool?

We were gonna do the double stud wall with the cellulose and never changed it when we switched to the 2x8. No other reason

These last 2 videos were amazing.

Would love to see more stuff like this, for example septic tanks/fields/residential waste water systems for tight lots or lake fronts vs larger yards and the costs.

Roofing materials with insulation, would be very similar.

Anyway, every week it seems I have a new favorite episode.

Matt I have been in the Trade all my life. Love your video's. Extremely informative! Keep up the good work look forward to more.

I wish you would have done a wall with the t-stud so we could see how that does in comparison to the more conventional methods you highlighted. Really good job showing these various wall assemblies!

Next week, framing with 11-7/8" TJI's LOL Love it though, as always, keep up the good work!

Matt, I know wood framing is your preferred build, but I think many of us would appreciate an identical analysis of concrete shells like, CMUs, Poured-in-place, ICFs, etc, and how to insulate, waterproof, bugproof, and costs. Thanks.

I'd like to see the numbers for T-Stud construction with Rockwool.

But with Zip R-6 sheathing

Looking forward to it too!

T studs with Zip R sheathing and spray foam them all together.

@@Rampage4635 I would not spray foam T-studs. In a fire, I would bet that the structure would collapse VERY fast. Hence, my preference for Rockwool.

Drew Morgan that makes sense

Matt,

I work for a GC in CA (super small operation just me an him, I only have about 4 years experience). We never do any of these advanced wall assemblies because code doesn't require them and most people aren't even aware of them, so even though the information is great I have no idea how to install this stuff. It's the hardware and proper screws and stuff that eludes me, and questions like "can the battens just be screwed to the plywood or do they need to go through the plywood into a stud" and "won't the rockwool compress if I send the screws home" and "how the heck do you install the windows in an assembly like that" and "can my home be retrofitted even though it would hang over the foundation by several inches" elude me. If you know someone who shows the details on how these are installed, a youtube video or a book, or even advice as to where I could go to learn about how to install these properly that would be awesome. Thanks.

I helped my uncle build his home, with R-50 walls and R-75 ceilings. He used 2x6 top and bottom plates with alternating offset 2x4 studs to break the wood's thermal bridge. The walls were insulated inside and out with 2" fiberglass, with 2" sealed foam board with inward-facing aluminum IR reflection. He added two more inches of foam board with outward-facing aluminum IR reflection on the outside, followed by siding. His attic was similarly snugged up tighter than a drum.

For air quality, he employed both an active and passive filtered, thermally-isolating air exchangers. While his similarly sized neighbors were paying over $200 a month in utility bills, his was never higher than $50. This was throughout the 1990s.

Matt, Great information. Don’t forget about your percentages for exterior vs, interior insulation in order to prevent condensation issues in colder climates. BSI-100: Hybrid Assemblies

You should do a video devoted to the permitting process! Love the videos.

Just the video I was looking for! Been watching lots of your videos and was wanting to see a comparison of sheathing and outside insulation methods.

We use comfort board r 20 on our low perm wrapped vermiculite cored masonry walls and wrap again for air gap before masonry veneer. We insulate and thermal break/vapor barrier the foundations or piers too. Do a lot of timber frames 10x10 post min. and glulam 2x12 for floor beams, bents get 8x8 min. Being in the north we have 70 psf snow loads. So thicker walls are norm.

Thank you Matt! Like that R45 wall! 💞❤️

Very interesting!

Would love to see a ICF wall compared too.

Definitely... that's what i'm considering...

ICF numbers are stated... r22-25 for standard. Zero breaks. They make new ones that are r-28. Best results high desert climate. The thermal mass ads some r like properties.

I wish Matt showed more interest in ICF. He's done a few shows on it but ICF really tackles lots of challenges Matt talks about.

NorthWoodsDiver zipp sponsors the show so that could be an influential factor

There are ICF systems that go up to R-59 and possibly higher. Pretty insane, and building out of them is basically the same as with any other ICF so any contractor familiar with regular ICF can use them. With all these exotic wood wall assemblies, there's a lot more that the builders need to be aware of, and not every contractor familiar with wood framing can do high R assemblies with their various caveats. In my opinion, at least.

I like how he appreciates his team

Thanks Matt! This level of detail is just great. I am loading your estimates for insulation (effective R) and $/sf (which will change over time) into our design programs to allow relative comparisons. Great Stuff!

Matt, this is exactly the kind of video which got me to subscribe to your channel. Amazing. Thank you!

I'd love to see some brick façade assemblies or even better a block built house, your series in Switzerland was super cool, I hope you can get on a plane again soon.

Very good info for builder or architect

I love your show. I've learned a lot. I would love to hear you talk about double wall exteriors for cost vs benefit. Thank you sir.

I totally agree with the Yeti cooler comparison and spending more money on the exterior wall to make the inside environment more stable and last longer. The thing I don't agree with is the HVAC systems are also more expensive and complex in all of Matt's other videos. There doesn't seem to be an option for building a Yeti cooler house and then saving money on a simple and reliable HVAC System. But I'll keep watching because I love the videos Matt.

I love these videos and have learned so much! It's been a dream of mine since I've been a kid to build my own house and I want it to be comfortable, convinient, and efficient. I love in northern cold climate, Idaho, and would love to know and learn more what kind of a wall is needed or can be done in my zone.

I did 2 x 8 top and bottom plates with staggered 2 x 4 studs. Blown in fiberglass dense pack for my 36 x 40 shop. Almost 4" behind every stud and more behind Outlet boxes. Cheap to build. Very little thermal bridging.

Woah that's interesting that you can use roxul on the outside, I never would have even thought of that. I can confirm that it does well even if it gets wet, unlike fibreglass. When I built my shed I insulated the floor and had scraps that stayed outside over the winter. After the snow melt I went to clean up the scraps and you would never even know they sat in wet snow and water all spring.

Suggestion Matt: Take a few 1m-cube boxes with each of the various

insulation methods, throw a thermometer in them, cool them all to 70°

...calculate how long per 1° increase on a day that's 90° (eg., typical).

Could you make a similar video but with different kinds of ICF construction and how they'd rank? Especially considering the different arrangments of siding you might put on them?

I’d also like to see an ICF construction with a Zip R-3-6-9-12(one of those) screwed to the exterior of the ICF. I’d think you get the extra insulation and the added water/weatherproofing. I’ve just wondered if that would be a good idea since now you’d have a solid exterior to attach your different types of siding.

The one thing Matt always fails to mention, is the more layer there are on the out side the more layers of drainage there are. A little detail that actually took me a long time to understand the benefits of.

Is anyone going to tell Matt that the way he says "Let's get going" is just like a late night infomercial for a knife that can cut a penny. #Ronco

But wait!

There's MORE!

I love it. I like his enthusiasm and his attitude, and I ALWAYS wish he was saying "but wait, there's more!"

Yeah but it makes me laugh every time. Its like the slap tape guy. "Thats alot of damage!"

Loving this series! A ton of info, well explained and detailed - thank you Matt & Co. In short you either make the investment upfront, or keep paying in additional energy costs over.

Matt...he’s all about the insulation 👍

Matt great video. Can you continue and do the same with roof systems. I'm really interested in a cathedral ceiling insulation system.

Wouldn't 2x6 or 2x8 walls allow for 24" stud spacing? Also, if you use two 2x4 studs to replace a single 2x8, would you save money and prevent a thermal bridge?

I think Matt saw those comments about how high his voice goes on his final “ooooon the build show” as a personal challenge. He’s now trolling all of you that complained about it. 😂

At this point his voice is higher than most little girls'. Not complaining, laughing.

dlwatib.....I anticipate it going even higher, lol

Excellent informative video Matt. Love the renderings as well. Would you do a similar video about roof assemblies please? Aslo curious about eaves details. Thanks so much for your videos!

one of the most interesting videos (that somehow I missed... for 8 months that is) if you ask me. I would like to know if there is a (calculated) point of diminishing returns on Insulation as expressed by R-value. The cost per sqft in the video are not horrible (unless you are building a very big house) but I would love to try to understand where is the sweet spot in R-value aim, mechanical efficiency of the house-as-a-system and then, from there, create a guideline intended to help new home-owner orient themselves in this field. Kudos to Matt and all the crews to make videos that are not only interesting and instructional but also funny to watch (funny to watch insulation video.. not a small feat if you ask me). Very well done!

You say these costs are “not horrible”. This video is from 9 months ago. I don’t know what the future holds, but current construction costs have skyrocketed over a short period of time.

I appreciate the recommendations for different regions

One other important thing to consider that wasn't mentioned (although hinted at) regarding polyisocyanurate insulation is... Polyisocyanurate's R-value diminishes the colder it gets. So it is less effective in northern climates unless used on the warm side of the assembly and then you have to consider vapor transmission. So maybe interior side of ceiling below the truss or rafter assembly provided the walls are vapor open (for northern climates). A more natural assembly could utilize 'dense pack' blown in cellulose insulation (which retards air movement), solid 1x board sheathing, heavy roofing felt, and comfort board insulation. The cellulose, real wood siding, and felt (tar paper) have a tremendous capacity to absorb excess moisture and dry out later. Many traditional and natural materials with much less embodied energy can and do perform as well provided the wall assembly is constructed with some planning and foresight.

Hi again . . . Nevermind my question below. I just found your video on window installation with exterior insulation. Thanks!

Blake

I want Matt to build my dream home one day!

Call me!

@@buildshow , you really emphasize the importance of water control in buildings. And bathrooms are exposed to water and vapor every single day.

I can´t wait to see all the details, materials, new products and techniques involved in the construction of bathrooms, ON ... THE BUILD SHOW!

For zone 6A a RESIST assemble with 2 inches of GPS foam taped, provides a flow through assemble. With 2x6 T studs and ICF you have a continuous air control and thermal control layer. That provides the monopoly framing and meets the perfect wall guidelines.

In Alaska I built a 2x4 with no cavity insulation and three layers of 2" foam. My 3000 sqft home costs $120 to heat for the coldest month. Others on the street with smaller houses and less wind exposure are paying over $300 for the same month.

Great Video. Awesome info with pricing, Finally! 👨🏾🦲

Here’s the complete overview of all the assemblies:

First Assembly: R-22 effective

2x6

R-23 Rockwool batting

Zip System (R-3)

Liquid Flash w/ foundation

$3.62/sqft

Second Assembly: R-25 effective

2x6

R-23 Rockwool batting

Plywood

Delta Vent SA

Rockwool Comfortboard

Tape w/ foundation

$5.82/sqft

Third Assembly: R-27 effective

2x4

R-15 Rockwool batting

Zip System

Atlas Energy Shield 2” Polyiso (R-13)

PT bug plate

Liquid Flash w/ foundation

$4.05/sqft

Fourth Assembly: R-30 effective

2x8

R-30 Rockwool batting

Zip System (R-3)

PT bug plate

Liquid Flash w/ foundation

$4.82/sqft

Fifth Assembly: R-45 effective

2x8

R-30 Rockwool batting

Plywood

Prosoco Fluid Apply (R-Guard & Joint and Seam Filler)

Two layers (3” total offset) of Atlas Energy Shield 1.5” Polyiso (R-9.8)

PT bug plate

Prosoco Joint and Seam Filler w/ foundation

$7.13/sqft

The tree spiel at the end was great.

Have you looked at all into offset double stud walls with blown in cellulose? I feel like it takes that thinking even further. Like embodied carbon of foam, rock wool and fibreglass are all kind of high. Whereas cellulose is a carbon sink.

It appeals to me especially up north where I live, we cannot wrap our houses in a foam.

On my old house there is 2 by 4 walls and only sheething innside, cold climate in Norway.

Doing renovation on it and changing the wall siding, put 2x2 laying on the whole wall and insulated the outside with rockwool then Tyvek vapor permable fabric and then one more layer pressure treated 2x2 for air flow and then the siding.

Love the tought of insulated house framing where it stays at a nearly constant temperature all year around

Everything of the stick framing is 60cm on center here or 23.6inch so there is a small scuare overlap wood only all over the wall but much better than whole stud wall exposed to the cold.

Could not get a hold on the firm rocwool type made for exterior use without 2x2 framing so just used regular for cavity insulation

This is such a good episode !

It would be nice to see insulation reviews start to show and include just how effective cork can be. Also, cork has many benefits to the environment. Is renewable, carbon sink, water resistant, vapor permeable, is almost perfect as insulation.

#9 is best in my opinion. Northeast, Indiana here.

Matt, please do a video on using radiant concrete flooring for heating AND cooling your home!

Living in South Florida our biggest threat is hurricanes. Any suggestions or maybe a video with some of these types of builds with concrete?

Being in the north, zip sheathing is making nervous because it's air tight. We need a vapor barrier inside the house, so if it's air tight on the outside as well, any water trapped in between may cause rot. There are many documented rot issues because of acrylic siding causing a similar issue where it is supposed to be water and air tight, but unavoidable defects (from install or from later modifications) end up causing terrible rot.

My house is a DELTEC home. The walls are 2x6 with a 5/8" plywood sheathing and then a 1" foam with fiber cement siding over. I spray foamed the walls with3" of 2# foam. The basement is ICF and we sprayed at least 3" of foam on the rim, licking to the foundation. Where I let down is on the attic. I let the insulation contractor talk me out of foam and also out of a vapor barrier. Seems that's standard practice in this area as I asked several builders and suppliers. However, Half of the house is tongue and Groove pine so being concerned about airflow through all the joints, I did poly that part of the ceiling. Still, It cost less for utilities on this house which is 505 larger than our previous home and Im also heating the 900SF garage. The walls of the garage are standard 2x6 with R19. I only heat to 55 degrees in the garage. We're in zone4 but it's actually fairly mild here in the winter for this zone.

Hi Matt this is a great tutorial on wall assembly options for different climate zones. What I'd LOVE to see is how you deal with windows in each of these options. Where is the window flange mounted (to sheathing)? Do you furr out the window openings so that you can attach the window flange on the outer face of the rigid or Rockwool comfortboard? My understanding is that ideally you want the window glazing to line up with the rigid insulation plane. Any details you have for the different options would be appreciated. Thanks, Blake

Are the 2x6 and 2x8 studs sill 16" on center or did you bump them out to 24"?

Having less studs means having more insulation which would improve performance and would adjust costs a bit as well.

Was thinking exactly that, should be 24" OC for 2x6/8. And of course, T-Studs!

These videos are amazing

Matt, could you do a similar video on staggered stud or double walled construction? I love seeing the Scott True builds you share cause it shows some great tips on how the everyday person could potentially afford a more high performance house without going ultra high end on some of the items. I'm not a builder, I don't know what lumber & framing costs account for in a typical build, but I am definitely curious if some hybrid type system - something with advanced framing, spray foam (flash & batt), staggered stud/double wall, can produce an even more affordably built home. I can see windows and doors being a bit of a pain... but at least in my area, two 2x4 are still cheaper than one 2x8.

MATT! What about T-Studs? I want to see the 2x8 T-Studs that are supposed to be coming out. Where is an assembly with those studs or even some 2x10 versions.

At this level why not just look at double 2x4s with firm packed cellulose?

Great content Matt. How about a double wall option?

I'd like to see you start to feature the science behind non-traditional buildings. I'd like to know how to insulate and seal a monolithic dome home, for example. Or how about the science behind cob walls and their ability to take in and release moisture in a beneficial manner for the house and occupants. I'd like to know the pros and cons of these nontraditional methods. I know this is not the kind of building that you do, but I would be interested in what you learn and have to share about this side of building science.

The diagrams were extremely helpful. I wish more of your videos used diagrams instead of or in addition to pointing to actual assemblies.

Love the content. For most people (like me) would probably want to upgrade their house vs build new. So guessing would have 2x4 or 2x6 construction with poor insulation value. Adding Zip/rockwool seems the way to go. What do you recommend on exterior facing material? Vinyl vs aluminum vs brick vs etc.? Have you run the numbers for ROI on attic vs house insulation? What gives the most bang for the buck?

Thanks for the info Matt! 😃👍🏻👊🏻

Would love to see about ICF walls and a SIP roofing. I’ve been looking at building a house in climate zone 2 in Arizona with a standing seam roof, and on the walls, half to be different color standing seam on top and rock face on the lower portion. I’ve seen some other people post about it and wanted to show interest.

ICF is great in your climate. A lot cheaper ways to insulate than sips.

SIP roofs get a lot of bad reviews. They are a disaster in Alaska, mold. Even in the desert u better keep the water out!

I'm planning a remodel/addition in Scottsdale and am working with some really amazing BS engineers where we're trying to get to a passive house standard. What I will say is wood-fiber insulation is amazing in our climate and is often overlooked as a product (competes with Rockwool so Matt doesn't have a huge play to mention it). ICF is good but the carbon footprint isn't good. However what I will say is if you do ICF, focus on exterior insulation and keep the interior mass uninsulated to allow for radiant cooling/heating during the day and charging at night.

Gerald Leenerts I’ve never heard of wood fiber insulation. I can put propane torch blue flame on Rockwool for a minute, it’s will not burn, it turns dark & puts out a little smoke but will not light & burn!

Yes in the desert the thermal mass (concrete) should be on the inside for maximum effect, but I don’t think it’s wise to use ICF & strip the foam off the inside....

@@GeraldLeenerts they have done studies it doesnt matter which side has more insulation. What is the carbon foot print of a house that lasts 200 years vs one that lasts 50

I like this, I've seen designs for high performance walls but they've always been so novel in construction that you'd need a special team to do it and you couldn't make the resulting house blend into a regular housing community. It would look odd and thus be hard to sell. By the way, I had my A/C guy in today for regular maintenance and as my units are ageing I ask what he's putting in new. I was asking about inverter tech, he said that split systems with that seem to perform really well and are reliable but putting it in whole house units has not worked well in his experience. They work well but they break down more frequently and are VERY expensive to repair compared to a regular unit plus they're more expensive in the first place. So you will have some energy savings but it will all be wiped out in just one breakdown.

Would double-stud walls be like 2x8 plates + staggered 2x4 studs? Seems like mostly continuous insulation (except at corners and plate seams/rim joists).

I’m getting ready to build a small home in Northern Kentucky; as a mildly cold and very hot, humid climate I’m curious about recommendations of how to design my exterior walls. I’m a mildly disabled veteran so I’m building on a budget so that I’m prepared for when my body won’t allow me to continue working. If it matters, I’m trying to make my design wheelchair friendly just in case I regress to that stage.

The recent wall framing videos were some of the best ones you have done.

Could you do a similar one on roof framing? You could use the stupid southern practice of locating ducts in a hot attic as Option #1. Then use conditioned attic alternatives for the rest.

I do have some questions about roofs. In the perfect wall concept, the control layers are continuous from the wall onto the roof. The same principles that apply to a good wall also apply to a good roof. So why do we build roofs differently than walls? On your monopoly house, you have a lower Zip roof deck, then two layers of polyiso, then an upper Zip roof deck. If two separated layers of WRB are bad for a wall, how can it be good for a roof? Why does Huber not rate the Zip-R product for use on a roof to control the thermal bridging there too? Are there other ways to control thermal bridging on a roof assembly other than having two separated roof decks?

In a 1 story house, you will have more roof sq ft than wall sq ft. So getting the roof done correctly and on budget is very important.

good presentation of comparative costs. Needs moar graph! and some sort of R/$ comparison to help folks find their sweet spot of cost vs R value.

Also some rough 'total square feet' for common house sizes, like '2000sq' house is roughly 1500sq' of exterior walls / envelope' as a baseline, with the wall types sq' costs multiplied out would give some sort of rough costing formula or gradient.

I'd love to similarly see the R value and cost per square foot of comparable insulated concrete forms.

I’d love to see you post the section details on all the roof and wall assemblies you’re using at your house on your website.

Instead of 2X8 framing try 2X8 top and bottom plates with double 2X4 studs. It stops the thermal bridging and reduces the risk of severe twisting. The double 2X4's can be tied together with a small 3/8 plywood gusset O.C. to stabilize and keep straight.

Matt,

Are the models computed using a standard 16" on center framed wall? What would the costs be if you used 24" on center with the plywood sheeting?

How's this compare to SIPS panels?

I build a house 20 years ago, I did the main level walls with SIPs. They had 7.25” of EPS so about R29 & worked very well in Climate Zone 5. They go up very quick but cost $$$

A good rule of thumb for SIPs is thickness of foam (assuming EPS) in inches multiplied by 5 + 1 for the two half-inch layers of OSB. So 8-inch total thickness would be (7 x 5) + 1 or R36. Not bad, but your air sealing must be flawless, especially in cold climates. In winter a lot of warm moisture-laden air is driven out through any gap (mistake) between panels and the moisture condenses against the outer OSB layer, which rots it. Other issues: SIPs are ordered to fit and not cut to fit on site. And pulling wires through those chases is a hassle, but I've seen the wire issue solved by fabricating a tallish baseboard to act as a wire chase.

Scott Miller Yes, wiring is a PITA. Floor outlets along walls is an option. American SIPs EPS foam are 3.5” or 5.5” or 7.25” or 9.25” They normally sit onto dimensional lumber bottom plate, also wall butt joints are 2x dimensional lumber shot together.

Man Matt, I really love my 1916 brick house but Its rough with air leaks. I wish someone had a channel like yours but for masonry homes.

same here

Love the vid,

question. What about horizontal 2x2 on the inside with extra batting. We use it here in Sweden.

What about non permeable plastic on the inside of the 2x4 in colder climates?

(Plastic between 2x4 and 2x2 for wiring, no need to penetrate any plastic that way.)

Next one for roofs maybe?

Thanks.

I'd like to see this as well. Very little thermal bridging, lots of room for insulation, ability to avoid penetrating the vapor barrier and no engineered components so inexpensive maybe.