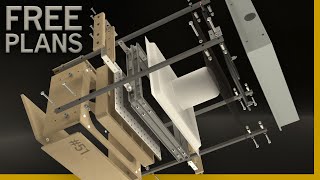

Vacuum Forming With Felt to Make Custom Product Enclosures!

ฝัง

- เผยแพร่เมื่อ 9 ก.ย. 2020

- Episode_048: In this episode we make a custom thermoformed enclosure for the RKDR 3 Retro gaming handheld using a Vaquform!

#vaquform #thermoforming #lulzbot #DIY #Maker #Fusion360 #manufacturing #digitalfabrication #retro #arcade #handheld #DIY #Engineering

Products Used in this video:

Vaquform/Thermoforming Machine:

www.vaquform.com/

Retro Arcade Handhelds:

shop.diy.engineering

Doublesided Tape:

amzn.to/2DQ0ovA

ABS 3D Filament for thermoforming bucks:

amzn.to/2ZYrmuz

Silicone Spray:

amzn.to/33obTXs

*You make the difference, please Like/Comment/Subscribe to support the channel.

If you would like to support DIY Engineering, head over to: www.diy.engineering/sponsor

Lets Be Social:

social.diy.engineering

Music:

Joakim Karud - intro

I was diving into how to do packaging things like this (Not just a cheap clear plastic in a paper box). This is a neat method, with a great video documenting it!

You're killing me with that laser cutting vinyl stuff... Love your videos

What a wonderful work!!! Keep on track man. So much inspiration. Saludos!

Great content! Thank you for these great videos!

Nicely done.

Beautiful!

Fantastic video!

Looks great. I love Thermoforming. I also love the bullet buttons on the handheld, nice touch. Game over man, game over! Maybe we build a camp fire and sing some songs ... HAHAHA

Hi, thanks for this great video! I would like to know that would it be possible to thermoforming directly from acrylic/ polyester felt fabric?

excellent vid, thank you. What adhesive did you use for the felt?

Have you considered doing any "Molded Pulp" for product packaging?

Is it possible to form/stamp the felt under pressure and heat aswell?

+ 1 Subscribed!

Hi, I would like to know that would it be possible to vacuumforming directly from felt fabric? I mean acrylic/ polyester felt not wool felt?

Hi, just wanna know how come you demold it easily without draft angles on the outer walls? Any tips on demolding things like this? Thank you hope you notice me 🙏

Vaquform doesn't seem to have the machine. It's nowhere to be found on their website.

The box is worth more than the device imo.

Flocking might be better

I hate to say it, but all that work and material for packaging is a waste, ethically and environmentally. Beautiful vacuum formed ahapes in felt & neoprene are great for custom seating and car interiors accessories but are thrown away as packaging; nobody keeps their fancy iPhone boxes, right?

'Making a simple housing with $10,000 of equipment'. Like my guy you did nothing here you 3d printed a simple shape, vacuum formed it on a $7,000 machine, laser cut things on a probably $1,500 laser cutter and didn't bother sanding or post-processing anything so it came out meh. 😂