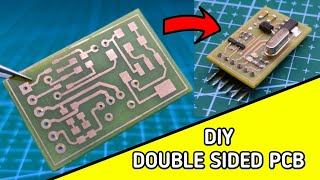

DIY PCB Toner Transfer (No Heat) & Etching

ฝัง

- เผยแพร่เมื่อ 10 พ.ค. 2018

- DIY PCB Toner Transfer (No Heat) & Etching

No need to use an Iron, transfer easily and fast!

No need to soak in water to remove paper, just peel and etch.

Music: The XX - Intro - แนวปฏิบัติและการใช้ชีวิต

Gareth, I tried to make this work several times, and got no where. It finally occurred to me that you're using nail polish remover, which isn't acetone; it contains acetone. A quick check of the product MSDS reveals that the specific gravity is .82 to .85; since pure acetone is .787, this means that it probably contains about 75% acetone (ignoring the confounding variables of aloe vera oil and scents). When I diluted my pure acetone down to 75% - 3 parts acetone to one part distilled water - I got much better results. I also found that a towel placed under the PCB - as you did - absorbs excess solution, and prevents it from being reabsorbed into the work, where it can cause damage. One difference I introduced was the use of a kitchen rolling pin; this allowed me to exert much greater vertical force, while keeping horizontal force at zero. Thanks for an excellent video. >Charlie

and thank you for the information and efforts

I tried this with acetone as well, and mixes of acetone, nafta, ethanol. but i did get it to work either with these things.. one thing that nail polish almost always contains is ethyl acetate,, so i suspect this is what is also needed, illl try some nail polish remover and see, it could also be a toner thing, as not all toner is the same.. im using a brother DCP-7030 with brother brand toner

@@0x2a1A4 , I'm also using a Brother BW printer with Brother toner. Gareth is - I believe - using an HP laserjet. Don't know whether it makes a difference or not. Keep me posted on your further attempts with nail polish remover; I never got a result as good as Gareths using any mix of acetone and water.

@@charlesworton4020 Laserjet 1100 according to 0:46 - I wonder whether that's with original HP toner?

@@DougWoodrow You have amazing eyes, Doug - thanks for the clarification. Only Gareth knows what toner he was using.

hello from Alberta, Canada

I am semi-retired now turning 65 years old this year. Took electronics in 1984-1984, Graduated with honors and began my electronics technician career.

In all my years I have made a few electronic projects but my pcb boards never turned out well. If I would have seen this 35 years ago I could have made so many projects.

I have a few on my mind now and was looking at how to get these done when I came across your article. Well done, many thanks from a former Brit born in Manchester, left in 1975.

Much appreciated you sharing this. I can't wait to try it!

Thanks, Gareth, for taking the time to pass along this great way of transferring the circuit design. I'm glad I won't have to buy another piece of equipment, just to use it for an occasional PCB.

I'm also impressed that you did it with one hand. Not bad at all.

Nice job sir! I've just made a couple of small nameplates this way onto bits of pre-painted wood. Works wonderfully and gives a very solid clear print finish. Opened up a new world of fun projects. Thanks.

This looks like the easiest method I’ve ever seen and your results look awesome. Hope I can do as well when I try it.

I used to make my own PCBs back in the day but I have never seen your method using the solvent. I am massively impressed. Thanks for sharing

Thanks for such a complete demonstration. I'm going to use your technique for my first etched pcb.

Excellent Video. Thank you for your time used to produce this. I am new to PCB making, and always appreciate input from someone who has already been there.

You are a genius. Your idea saved me 1month waiting for the material which is not available in local stores here.

Thank you very much

"Heat the oil in a large pan over a high setting. Add the onion, garlic and chicken and cook until it browns" - Got it ! Thank you very much.

Don't forget to add the etchant, for enhanced flavour! Trust me, your guests will _die_ for it

This is one of the best toner transfer systems I've ever seen !!! Congratulations!!!

This is a super easy method for super professional pcb etching! Thanks a lot. I regret that I never came across this video earlier.

Thank you for this tip!! I used to use this method using a clothes iron but it was very sloppy. Definitely going to try this on my next project.

Thanks again!

-Ant

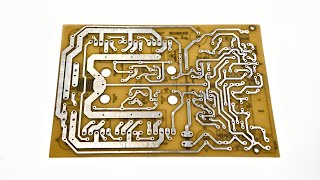

after a few imperfections, I'm now getting perfect results nearly every time. Total game changer! Thank you Gareth.

Going back in years before pc’s and home printers I used to draw out the track with nail varnish, quite crude but either on very simple pre-IC circuits. Definitely will try this method now I have all tech in hand. Thanks for sharing

By far one of the best how to on TH-cam for a diy pcb. I've watched this a few times. Dude! You make it look easy!

Thank you man! I've always strugled with the heat transfer and your video has just saved my life. Definitively going to share this everywhere. Greetings from Guatemala.

Fantastic video- I have tried the toner transfer method many ways, but it's hard to do reliably with pressure/heat, even if you have expensive toner transfer paper. Thanks for sharing.

Couple things I will share that helped me:

1) The final step (removing the toner after etching) works great with pure acetone... it just slides right off in a couple wipes. No risk of abrading/tearing small copper features

2) Ferric Chloride liquid can be hazardous/expensive to ship- try ferric chloride anhydrous (dry powder, add water to make acid)

3) Etching is messy; most reliable/clean way I've seen is with Ziploc bags (double-bag!). Sand off sharp edges of board; fill bags 1/2 full of acid & drop board in. Seal both bags. Rub gently with fingers & slosh acid around. "Massaging" the copper increases etching rate a lot and you can work the areas that need it most; best of all, you can bring it to the top of the acid & see progress as often as you like. Takes a couple minutes; Pull out board & reseal bags or dump acid into container. Hardly spills a drop.

That's PCB rock-n-roll! Just what I was looking for to make my new planar speaker headphone membranes!! Thanks!

This is awesome. So much easier than methods I've used and less expensive. I'm going to try this on my next project. Thanks so much!

Absolute genius! Thanks so much for this.

Your approach is so neat. After drilling holes, to remove the black transfer from the copper lands, use acetone on a cotton schwab or cloth, being careful not to destroy the top surface component placement. Much better than the steel wool approach.

A student of mine, Greg Smith, got me interested in electronics around 40 years ago. Haven't done much since then but now I am retired with a great hobby. After watching your video I am ready to try PCB making. Thanks for a great introduction.

That's a very interesting method that I now have to try.

Over the years I've had many problems with the iron method, I've also modified laminators to increase the temperature but had little success...

Wow this is just what i needed, building a big muff guitar pedal and i'm just at the stage where i need to transfer and etch, Thanks Man!

Brilliant. I use this process now for all my boards and it works great! Thank you Gareth!

Brilliant method. I was not going to do any proto PCBs until I saw your vid. Thank you for taking the time to edit and shoot this instructional.

The best DIY PCB etching to date! Thanks to your clever tip, mate!

Great job Gareth!

I’m really impressed with the resultant quality and simplicity of your method.

I guess it would become my favorite one.

Greetings from Russia )

So simple and effective, wish I seen this a little earlier. Thanks so much for sharing!

Single handedly. Amazing work !! Thank you !

So damn simple, quick and inexpensive. Used to do it the "hard way". Always have plenty of "transfer stock" on hand. Thanks for sharing.

Tried this myself with pure acetone, different types of glossy magazine, different pressures and different durations soaking the paper. Only one gave a partial transfer. Then I read a comment here about adding water to the acetone (2 parts acetone, 1 part water) and it worked! (Samsung toner).

Definitely some chemistry taking place as I tried different colour toners, they start out the toner colour at the time of transfer but then slowly change and become darker. So I would suggest giving it time to rest before etching to 'cure'.

I confirm. Acetone works well with water (1:1) and glossy magazine paper! 🤔

laser toner dissolves in acetone but not water. with the right mix of acetone and water you just get soft, sticky, tar-like toner that sticks to the copper and the water weakens the paper enough to peel it off.

Thank you Sir

God bless you and your family

wow, this will change the way I make boards from now on.. great stuff!!

THANK YOU!!!! THe heat transfer method was always 50/50.. Sometimes you get too much pressure or heat and it flattens out, other times its too cold and doesnt stick. this looks VERY promising!

THAT'S AMAZING- YOU MAKE IT LOOK SO EASY!!!

Tried this this afternoon, on a piece of scrap board with 0603 smd components. The results where perfect first time. Very professional looking board that worked first time.

Thank you for sharing this method its now my preferred method of prototyping.

wait, you tried it with 0603 components, was it a double side..kindly share that.f%^&in amazing

Grahame Skate please show a video

So cool! I'd have never thought of that. I was about to go scrounging for lamintors and instructions on modding them but this seems like a better method, and cheaper.

Fantastic! I can't wait to try that. Nice technique, well done. Thank you!

I used to do something similar to this, everything exactly the same except I used an iron instead of nail polish remover to transfer/melt the toner from paper to pcb. Your way seems to work better though as mine was a bit hit and miss! thanks for the video.

Congrats mate, u made it one handed while recording. Thank you.

The moisturising polish remover is the surprising agent that affiliates the process. Thank you for the awesome video.

Every Once in a while you come across a decent real info and great video, so Thank You, This is very good!!!!!

Hi Gareth, thank you very much. I'm deeply impressed. After using the iron for years i still had pcbs that didn't looked that great. I tried your method with three different polish removers and a piece of gift wrap and it worked right from the start. Unbelievable!

One thing for German etchers: I used the "today Nagellackentferner, acetonfrei - mit blumigem Duft" from REWE

Unbelievable !! Thank you for a nice video...You are genius,

Thank you for sharing, I will try this method!

The title ought to read - _"DIY PCB Toner Transfer (No Heat) & Etching

- with _*_one_*_ hand"_

Every respect for coming up with this brilliant no-heat transfer method! I've not etched anything in years but I will try this for sure. Thanks!

I understand that the additive that is used to make glossy magazine paper is China Clay.

this was such a great video! really enjoyed that & what a great method!

I have used your exact method with my high school electronics class and have had great success. You have simplified my life and health and safety issues and provided an expert level result with very little cost.

WELL DONE!!!!!

High school electronics class? Where do you go to school?

Amazing method...I´ll try it as soon as I can get the nail polish remover..thank u so much!!!

Congratulations!! Professional quality on DIY PCBs. Nice video, well done!

It's a huge upgrade of iron method. Man, where you've been ten years ago? You could make those 10 years much easier for me ;)

Did you tried another method of screen printing??

very nice. and all with one hand...a true maestro! 80) I ended up with crumpled paper jams, tape peeling inside the printer, and pitting where the fuzz stuck to the toner...but i think i'll give this a go with the dozens of old maplin magazines i chopped up.

I used an aincient HP laserjet 1000; but it wont feed anything but perfectly flat dry paper, a new Brother 2365 laser (bought especially) is abysmal; it seems to rush and try and save toner, no matter what settings its put on...i found a setting that 'should' have worked..it managed to singe the paper! very impressive...NOT.

yet someone else from the UK on 'the 'tube' has done TT (iron-on) using the dog-cheap 'tesco's special' Brother Laser...meh.YMMV

Glad I came across this video, looks like a great way to do it without an iron or modifying a laminator. Thanks.

Dear Sir, I don’t know how to thank you for sharing this method which is much better than transferring the toner with a hot iron. It’s not giving good results and sometimes the heat causes the copper layer to separate from the plastic. I followed your method using acetone instead of that polish remover I couldn’t fine here. It gave the same result. Just brilliant. Thanks again my friend. ☺

Nice technique, well done. These days I engrave all my boards, but I'll try your technique for silkscreen. Thanks for the video.

How do you engrave your board ?

@@thecongo8505 I have a few videos on my channel going through the engraving process I use.

@@TheStuffMade Thanks bro

Great ideas! Thank you. I'd just add that if the layout is done with a copper 'fill' in all the empty spaces it uses up hardly any of the etchant's strength, makes the etching go quicker, and makes it last long enough to allow you to do additional boards with the same etchant.

And depending on the design, it could create an excellent ground plane and/or shielding.

Great job man! Thanks for sharing. I'm going to make my prototypes right now.

Great information you have parted to those who are hobbyists who cannot afford to get the Pcbs of their circuits then and there. Thanks a lot for the help.

Great video man, the best and easiest method for DIY PCB making in youtube so far.

Any body can make a video with expensive printers and special papers but no all the viewers will be able to follow their style.

Your's is unique man, All house hold items used.

I like your style, Make it simple with what you get( The actual DIY way)

Keep making useful and simple videos like this man.

🥳✌️👏👏👏

Sure but honestly, my printer is the cheapest 99$ canon with integrated scanner, I also use junk mail to print on (no need to tape it to printer paper first) and yeah I use a small, unmodified laminator, no need for expensive stuff

i don't think ferric chloride is a household item

I'm quite impressed (and surprised to be honest) that acetone can do such a great job transferring toner on to a copper. Great idea! Kudos to you, sir!

it was very impressive indeed ... so much easier and quicker than screwing around with a 3D printer to etch a board - aka, ruining a perfectly good piece of blank copper pcb, because most of the attempts I've seen took over an hour for even small boards and totally munted the copper tracks up.

He really should have been wearing gloves for the acetone part too...

Этот способ давно известен

@@qumefox nail polish remover is designed to be used without gloves

@@AlessioSangalli you generally apply nail polish remover to the fingernails. You don't soak your whole hand in it

I have spent years making pcbs by the old heat transfer method and you have just brightened my life. 😎✔❤😍

Wow, that's the simplest approach I've seen so far.

It's been _decades_ since I made my own PCBs as a young hobbyist. Drawing the traces with a sharpie and etching with FeCl3. One thing I remember discovering very early on was that a PCB floats on FeCl3 if you place it on the surface gently. You can then avoid stirring since any etched away material will simply fall off and sink.

You could also attach a piece of styrofoam to the opposite side, using double-sided tape or even hot glue. This will allow the pcb to float on top of the ferric chloride solution. Then you have the ability to agitate the workpiece or remove it to check your progress without the risk of it sinking.

Why so many dislikes? You just got rid of the damn iron! This is great! Perfect!!! Thanks.

I make a lot of PC boards and have been using PNP blue transfer paper. But this looks really interesting. I'll have to give it a try. Thanks for the info!

Congratulations my friend the best method and what simple without an electric iron !!!

I'm from Brazil!.

Congratulations on your contribution; really enjoyed.

thank you.

Funcionou?

i do the same thing but i just use the big containers of acetone you get from lowes or home depot. i do use a flat board to apply pressure though so its even across the board. i've had some traces get distorted if the pressure is uneven.

you saved me, after years of trying and failing. thanks for sharing.

Fantastic! I can't wait to try that. Thank you!

I got this way to work quite well! i bashed out three PCB's yesterday. using a brother laser and semi-gloss finish office paper; it peels without leaving fuzz embeddd in the toner; i used it because i had some, and my printer tries to burn magazine paper...! you may get away with any old crap. 80)

Clean the copper using Acetone, NOT nail varnish remover which, as well as being over-priced, contains oils to stop drying of the nail and a large percentage of distilled water...neither of which help at all for this purpose! the stuff i used is about 98% pure, and sold in the 'cleaning-products' isle in the local supermarket's for around 4 euro's a litre. Wipe the board dry with paper tissue. keep your oily fingers off the copper.

I soaked the BACK of the paper with a few drops of acetone, which seeps into the paper and dissolves the toner; the reason i soaked the back was to make sure the toner was well dissolved and to avoid smudging the tracks when placing it on the copper. (if you drop acetone on the brother toner it almost dribbles off the paper) the ideal is nothing between the toner and the clean copper...and that includes a layer of acetone... While the paper is still wet, place it carefully onto the copper PCB, press down with your fingers or a flat board padded with tissue ( i used a rubber roller from a dead inkjet printer to roll it firmly on) leave to dry.

Soak board in warm water (NOT hot! you don't want to re-fuse the toner ) warm water seems to speed up the 'soaking'; which releases the paper/clay from the toner. you may get away without soaking. Peel off the paper, and you will have the toner firmly stuck to the copper by some strange alchemy... Any traces of the clay used to make office/magazine paper 'shiny' can be gently scrubbed off using your fingers. Etch, and grin like a loony at your wonderous new fab lab.

Hack In Black what min trace / spacing could be achieved?

@@Grants2251 technically it depends on the resolution of the printed image, for me a trace width of 6 mil and 4 mil spacing worked.

Holy fuck dude. That was great

Do you have a video of your method?

can you show how you did this?

When you etch, try to put carefully PCB upside-down to float copper side on surface. Copper will fall off from PCB better. Look out of bubbles only. :-)

The best DIY printed circuit board single layer procedure I have ever seen.

Thank you, very creative method for trasnfering the pcb toner. For corrosion process I use a combination of hydrogen peroxide+sulfuric acid+faucet water; I've used it for many years with very results.

Super Awesome !

Swap the FeCl3 for Vinegar, Salt and Hydrogen peroxide and all the design/etching materials can be bought in the supermarket !

In the UK they swapped the Acetone in nail varnish remover for Ethyl acetate some years ago.

Use gloves with either solvent - they tend to transfer through skin, bringing whatever they dissolved with them.

In what ratios?

I really didn't bother measuring. Mostly vinegar, loads of salt and a small amount of peroxide.

Fortunately this would be very easy to experiment with on a very small scale to find the exact proportions of each that would work best for the vinegar/peroxide available to you.

It would be hard to make it not work, just better if it goes as fast as possible.

My vinegar was 9%, the peroxide 3%.

aga Or just buy acetone

Every day i discover new amazing things in this life. Huge thanks for this, it saves the most important , it saves time. I cant leave without sharing lifehack. If you screwed up with hot glue, just poor it with isopropyl alcohol, and hot glue will fall off almost instantly.

damn really? I wonder if that goes for medium heat glue and high heat glue.

Ok life hack... hmmm. Use 3.5mm audio jack cables as "wiring harness" for sensors that require 3 wires. Just make sure audio cable has 3 wires. makes a quick disconnect to sensors and looks tidy.

@@thedillestpickle I have only one type of glue in my area, I assume that if heat glue has the same chemical structure, isopropanol will work . As for sensors - 3.5 mm jack is really better than those small breadboard pins.

@@wickeddubz hmmm that's really cool about the alcohol.... I put my last project in the oven on low and used a spatula to pry off the hot glue LOL.

Yea those breadboard pins don't inspire a lot of confidence. I

@@thedillestpickle I tried to remove hot glue from my project (modded small ikea table) , but I saw that if i continue to remove it mechanically, I'll screw up everything. Few minutes of intensive search and websites crawling helped a lot, all glue just fell of instantly. Chemistry rocks :)

thank you sir for being unselfish from your talent and skills

I used to use a thermal pocket laminating machine I modded with a custom controller to make my custom PCBs... but I put it somewhere safe and can I find the darn thing now I need it. This not only gets around that problem it shows how to do a silkscreen too. Thank you.

A small "speed-up" hint for the etching portion: After you transfer the toner and wipe it with the sponge, use a hot air station (or heat gun/hair dryer) to warm the copper. Take the time to warm it up and when you dunk it into the ferric chloride, you'll see bubbles and it'll etch at a much higher rate for the next minute or so.

Another hint: Next time make a large ground plane. You'll use far less etchant. :)

That's neat! I was wondering how heat would effect this process.

Years back when I did these, I placed the ferric tub in a tub of hot water. The heated ferric was much quicker, I just rocked it from side to side.

Thanks I will implement this in my project

@@humbughumbughumbug I find large ground planes difficult to solder without bridging, since the at-home pcb method has all of the copper exposed, vs having lacquer covering the copper in the spots where there are no components.

Great video... when etching the PCB, I prefer to put the PCB upside down.

Surface tension helps to keep the PCB afloat on top of the ferric chloride.

Assuming the "resist" is reasonably strong, I put my boards in a little plastic container (one with a snap on lid), such as you will find holding lunch meat, and then shake it fairly vigorously. The etching goes real fast this way.

Tks a lot Gareth, now I can learn to make my own PCB using your method....

Handled single-handedly! Awesome, thank you!

Everyone's like "man his PCB looks great" but I'm trying to read that chicken stew and rice recipe...

You are a magician? Одной рукой снимает, другой колдует. Чувак - волшебник.

xaxaxaxaxaxa

I have made many boards with toner transfer using a laminator to fuse the toner to the copper. But, this takes the cake! I can't wait until I need a board to try this.

Ive been doing it wrong for years LOL ! Thanks for sharing....and improving my life considerably !

I've reached significant improvement by using other mixture of chemicals and their ratio and that is 8:3 alcohol and acetone (both pure = assurance of real volume of chemicals). But the magic was actually in using rolling pin :) I've combined other manuals, very similar to your video. Many thanks for inspiration!

I was wondering about using something that rolls.

I have a few rollers that were from old printers/scanners. I have a couple that are reasonably long and could cover the entire board.

As I typed that, an idea popped into my head!

Perhaps designing/building a automatic roller, using Arduino and a stepper motor might be cool. You'd put the PCB into the roller plate and the Arduino would control it to go back and forth, slowly, applying a bit more pressure with each pass (up to a max pressure point).

Yeah yeah... not necessary, just fun. LOL

@@BlondieSL Exactly, just fun :) Btw, I've also tried the other approach of toner transfer and that is by heat. But I didn't found out a proper paper, also in that way a equally distributed heat and pressure (!) is even more important. I saw a few tutorials and those guys used a fine tuned roller from lamination machine.

Rolling pin is a good idea. How about a brayer? As long as the nail polish remover doesn't dissolve into its roller and make it sticky..

@@earthlightsmusic2743 Well, there is no other way how to find it then try it :) But I guess that pressure wouldn't be such uniform and sufficient as with rolling pin. If you're going to test it, let me know about the result, I'm interested.

1:20

The proper choice of magazines as a source of the paper will make your PCB making process even more interesting :-)

@Maxim Bulkowsky So, from now on, when we'll see a small-scale production using this method we'll know it's backed up by a solid Playboy collection. :))

most of the work done with just one hand ... great job!

Man, if I had seen this video a week ago... I will definitely try this next time, thanks for sharing!

Could you do a video about drilling holes for the trough hole components on the PCB?

Молодец! Отлично получилось, особенно если учесть что делал всё однй рукой. Для тех кто не знает английский язык - использовал жидкость для снятия лака.

Вот не ожидал увидеть здесь коммент на русском! Удивил! А автор действительно, качественный лайфхак показал.

Непонятно - ацетон подходит или нет?

А вот и сама формула: www.instructables.com/id/Heatless-cold-Toner-Transfer-for-PCB-Making/

Никакой спирт не нужен - ацетон с водой идет прекрасно! Соотношение подбираем - мне сходу подошло 1:1, но может с другими пропорциями будет лучше - пока отложил эксперименты после получения первого прекрасного результата. Причем да, нужен глянцевый лист из журнала - бумаги нет 100% перевода по причине того, что тонер от нее не отстает так здорово, как от глянцевого листа (причем тонкого - какой-то очень бюджетный вариант журнала попался, почти как газета).

Так же подходит жидкость для снятия лака, но шоб с ацетоном - без ацетона на глянце не успел попробовать, но во время эксперимента с обычной бумагой тонер с нее ни капли не лип к меди, вообще - как-будто водой лил, когда жидкость с ацетоном почти все с обычной А4 (!) бумаги переводила на медь ...

Very nice and clean method. I'll definitely try this. Thanks for sharing.

Thanks for posting this. I was about to get an old iron to try the heat transfer method, but I will try this method first.

You could improve the silkscreen layer by drilling two key holes in the board first and lining them up with holes in the print

I would do that Michael. Hoping for a perfect line up is too hit and miss without some register holes/pins. Good post....

One hand?? Jesus I couldn't make this toner transfer work even if I had 3 hands.

I have no descriptive idea what happens when the toner is masked to the print. Then shows coming out of the printer? No description in between. Not an easy Presentation for me. I guess I've better talk to a local expert...

@@kg7aronny I think that he printed out the images onto A4, then stuck the magazine paper over them and pushed it back through the printer to reprint the image directly onto the magazine paper.

@@kg7aronny you export the circuit as pdf and print it as mirror image. pdf keeps it to scale and mirror on the copper makes it like on the pc screen.

It looked like some one doing a difficult task with four feet. Hahahaha

@Pablo PabloBrawo.....intelekt z Twojego "otworu" przez 4 palce dotarł do Twojego mózgu.... brawo

Gareth, this is a brilliant result! I'm looking forward to giving it a try myself. Oh, a channel named Nurdrage has published a simple formula for home made 'liquid tin' - you submerge an etched copper board in the solution, and it instantly plates it with tin. MG chemicals makes retail 'liquid tin', but it's horribly expensive - the nurdrage formula is much cheaper. Haven't tried it yet, but I've bought the components.

And, another TH-cam site - chemistry games - has published much the same formula, but working from laboratory pure chemicals, rather than using commercial products, found on store shelves, that contain the active ingredients. I've ordered the pure chemicals, and will do a video comparing the two approaches.

And of course, there's always electroplating. I might try that as well.

I've come back to this video several times, and watched it from end to end. I REALLY like your result - absolutely one of the best I've seen. I'm definitely going to try it. Spectacular work! >Charlie

Brilliant work, I was about to buy thermal transfer paper to perform the etching, thankfully I saw this video I really appreciate you sharing this will definitely be trying it out today. That silkscreen method is really the cherry on top it's so well done.