RIM AND FACE ALIGNMENT FORMULA METHOD | ENGLISH | Rotating and Static Equipments

ฝัง

- เผยแพร่เมื่อ 3 ส.ค. 2020

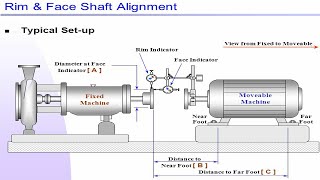

- TOPICS EXPLAINED: RIM AND FACE ALIGNMENT FORMULA METHOD COMPLETE PROCEDURE AND DEMONSTRATION WITH EXAMPLE READINGS.

PRE-ALIGNMENT PROCEDURES, STRAIGHT EDGE METHOD, SOFT FOOT, BAR SAG, VERTICAL MOVEMENT FORMULA, HORIZONTAL MOVEMENT FORMULA, ALIGNMENT CALCULATION. ALIGNMENT CORRECTIONS, CRISS CROSS TIGHTENING PROCEDURES.

Join this channel to get access to perks:

/ @rasetech

REQUIRED TOOLS:

DIAL CLAMP FIXTURES, DIAL INDICATORS, STEEL RULER, MEASURING TAPE, TRY SQUARE, FEELER GAUGE, MAGNETIC STAND WITH DIAL INDICATORS, VERNIER CALIPER, OUTSIDE MICROMETER, INSIDE MICROMETER, SPIRIT LEVEL, MIRROR, PRE-CUT SHIMS, SPANNERS, AND TORQUE WRENCHES.

SUBSCRIBE FOR MORE ROTATING AND STATIC EQUIPMENT VIDEOS.

/ @rasetech

RIM AND FACE ALIGNMENT FORMULA METHOD | TAMIL

• RIM AND FACE ALIGNMENT...

HOW TO FIX SHAFT ALIGNMENT SOFT FOOT | ENGLISH

• HOW TO FIX SOFT FOOT O...

RIM AND DOUBLE FACE DIAL ALIGNMENT FORMULA METHOD

• RIM AND DOUBLE FACE DI...

RIM AND FACE DIAL ALIGNMENT TOOLKIT FOR META FLEX COUPLING

• RIM AND FACE DIAL ALIG...

HOW TO FIX SHAFT ALIGNMENT SOFT FOOT

• HOW TO FIX SHAFT ALIGN...

BAR SAG | ALIGNMENT

• BAR SAG | ROD SAG | S...

REVERSE DIAL INDICATING FORMULA METHOD ALIGNMENT

• REVERSE DIAL INDICATIN...

REVERSE DIAL INDICATING ALIGNMENT|OPPOSITE DIAL POSITION|FORMULA METHOD VS GRAPHICAL METHOD

• REVERSE DIAL INDICATIN...

REVERSE DIAL INDICATING ALIGNMENT|CROSS DIAL POSITION|FORMULA METHOD VS GRAPHICAL METHOD

• REVERSE DIAL INDICATIN...

CENTRIFUGAL PUMP OVERHAULING PROCEDURE | DISMANTLING AND ASSEMBLING | ENGLISH

• CENTRIFUGAL PUMP OVERH...

BELT DRIVE PULLEY ALIGNMENT STRAIGHT EDGE METHOD

• BELT DRIVE PULLEY ALIG...

CENTRIFUGAL COMPRESSOR DRY GAS SEAL SUPPLY SYSTEM

• CENTRIFUGAL COMPRESSOR...

RECIPROCATING COMPRESSOR PISTON OVERHAULING PROCEDURE

• RECIPROCATING COMPRESS...

CENTRIFUGAL MULTISTAGE PUMP ROTOR IMPELLER ARRANGEMENT

• CENTRIFUGAL MULTISTAGE...

HEATLESS DESICCANT AIR DRYER AND OPERATING TIME SEQUENCES

• HEATLESS DESICCANT AIR...

STUFFING BOX SQUARENESS|BORE CONCENTRICITY|SHAFT RUN OUT

• STUFFING BOX SQUARENES...

HOW TO SELECT SPANNER SIZE FOR BOLTS AND NUTS | INCHES TO MM | MM TO INCHES

• HOW TO SELECT SPANNER ...

DUPLEX BEARING ARRANGEMENT IN SINGLE ROW ANGULAR CONTACT BALL BEARING

• DUPLEX BEARING ARRANGE...

#rimandfacealignment

#rotatingandstaticequipments

#shaftalignment

![🎮เกมยิงปืนใหม่ ภาพสวย และ สมจริงที่สุดในโลก [ BODYCAM ]](http://i.ytimg.com/vi/My3l1owRY9I/mqdefault.jpg)

Easy to understand. Good clip.

THX

Thank you for the explanation

🙏🙏🙏🙏 Good explanation it will help a lot to the rotating equipment developing Profesionals 🙏🙏🙏🙏

Superb explanation dear.

Thank you.

There is a mistale my friend in vertical correction :

+add shims

-remove shims

Dear Friends,

Recently I have uploaded tamil version of this video in our channel. Kindly please check it out. Thank you.

th-cam.com/video/3qZK73sU5Wk/w-d-xo.html

Thank you teacher❤

Thankyou very much sir.

Very nice explanation for allotment job 👍👍

Thanks bro teaching in English

Thank you sir.🙏

Dear Friends,

Recently I have uploaded Hindi version of this video in our channel. Kindly please check it out. Thank you.

th-cam.com/video/8xeIqVVPFN4/w-d-xo.html

Very useful sir, please keep up downloading more videos regarding Shaft alignment with English explanations.

Thanks for your support. Thanks for checking out my channel.

Hi. thanks for the video but i would like to make 3 questions.

1) where is the distance of the couplings calculated in the formula? as i could see you dont need that diamension to calculate the shims, right?

2) instead of using the stationary machine shaft to mount the dial indicators can i use the the movable machines shaft? if so should i look anything in the formula results? (inverted numbers etc)

3) Should i rotate both shafts when i make the procedure to take the measurements? or just only the one shaft that the dial indicator is mounded it?

i have an application that should proceed the rim and face method but the stationary machine has a drum style end and there is no easy point to mount my dial indicators.

Is it possible to convert face and rim indicator readings to reverse alignment indicator readings or vice versa? If possible how?

Do you have another formula by using dial indicators for this?

Thanks bro

Welcome bro

Many thanks for the great explanation!

I have one concern, in 6:45, did you mean we have to rotate the shaft from 12 to 6 o clock and then zero face indicator and adjust rim indicator at -0.04?

Then rotate shaft to 12 o'clock and taking the reading?

Thanks,

Yes brother...

Salamat in Philippines means thank you...it will help me more

You are most welcome...

Many thanks

Question ! My coworkers always taught me since I began this trade to set the fixture on the moveable and the indicators onto the pump . Does that alter the readings what so ever ? It seems to have always worked for us and brought us with 1 thousandth

I didn't understand your question bro. You can set the dial on pump coupling and take reading according to the same you can correct it. it is upto you and understanding. that it. bro

Hi sir....good video...but i hv one question...regarding on the clockwise position...is it we refer from motor side or pump site...i mean the position we standing...tq

Thank you I'm waiting for english version.

You are most welcome...

Sir about the value you make +0.06. As i know the valu usually like 250, 280 something like that

What is the formula of radial misalignment at coupling is that = TIRF/A *100 ?

Kindly make video on reverse alignment

Nice explaination but I have one doubt

Can we find both virtical and horizontal reading at only once set dial indicators on rim and face

It is really helpful vedio. Can you share the calculation method for revverse alignment thank you

Thank you ❤

Sir some couplings come without space directly coupled how to do alignment for those couplings please put videos for how to do alignment for those couplings, jaw couplings

Yes we need to prepare special fixtures set for those direct couplings.

Bar sag value . Is bothe bothe saft rotat togather 0 to 180 ?

Thank you very much it was great explanation,

can please you send the pdf or post it so that we can download

because it will be easier to do it with these papers.

Dear Sir,

I kept these papers in my home now I am in abroad. So Now I cant able to send these soft copy to you... apologize for the same. even I want to search the related papers from my room. You can take notes from the video or you can take screen shot. Thank you for understanding ❤

Waiting for Rim&Face graph alignment

Sir,One more question if you allow- During FFH & BFH-shifting After having reading FFH-0.08 mm & BFH- 0.48 mm respectively when I Shift the motor from Front side 0.08 mm at the same time the back foot dial indicator also move little bit my question is can we include those shifting difference under obtained resultant BFH shifting reading - 0.48 mm or we add this difference+ 0.48 mm? & Grinding the base bolt for motor movement if motor base hole touches the bolt and doesn't allow to move further is good or bad?

very good question. I appreciate it. First we need to correct higher value. So BFH is bigger value rather than FFH. So we need to correct BFH and at the same we need to monitor on FFH side also. While adjusting BFH, FFH will reduce automatically when it is reach required target we need to hand tight and touch the FFH opposite side jack bolt. then again continue with BFH to reach our target. I hope you understand this. Still if you have doubt. please let me know. All the best❤

@@rasetech Thank you sir my pleasure.

Good Video, I would like to know, What happens if we cannot rotating the shaft of Station machinery (compressor cannot rotate)

We set alignment bar at motor side and Rotate shaft of motor only , this method and formula still complied or not?

You can. but you cant eliminate the runout of shaft or coupling if presents in the machine. and you will not get the exact reading. it will be increased or decreased due to runout.

@@rasetech I would like to speak to you regarding one on one training, could you please let me your contact email address.. my email id: kumar0369k@gmail.com, thanks.

@@anilkumar-xe5mh prakashmagalingam2020@gmail.com

👍

When this method is used?

Why we are checking RIM bar sag only??and is it necessary to take sag value at 3'o clock and 9'o clock???

Sir Hindi me bhi upload Karo plz

Rotate 360° sir? Or 180° only? Thanks for reply.

What is the formula for clamp fixing in the motor and dial fixing the gearbox coupling?

all are same formula only.

as per your dial setting from 6 o'clock to 12 o'clock and if getting reading +0.2 but if I setting dial from 12 o'clock to 6 o'clock should be applied formula -0.2 ?

Yes only we need to change the sign. as per your setting if ans is plus then add shim if minus means remove shim. that it brother.

Sir 👍🙏 good time iam watching your videos but I riyaly Miss you sir my experience 2005 to 2023 till date continues job eraction 240 mw ,500mw& steelplant& gas plant & tyreplant millwright fourman ,chargent, mechanical incharge millwright job rotating assembly supervisor for gt so meny job done 👍 for it very nice 👍 your full promotion video my total experience in one of your video 💘 broken 💔 my heart sir your the master assham how can't act you sir 👍.

thanks my number 8680032253

Please upload every videos in your channel in English also....it’s a request

Thanks for your comment. Well noted.

What is bar sag and why it is required. We are rotating rim dial indicator on a shaft, suppose that shaft has some surface irregularity then dial will show some false reading. Please help Anna to solve this confusion.

Dear Brother,

For bar sag I have uploaded a video. here we go.

th-cam.com/video/BjaKWIZXVWQ/w-d-xo.html

On the 6:36 how much we rotate the shaft to get the R and F value? Is it rotate full 360° ?

No its 180 degree...

@@rasetech thanks sir, and how about coupling spacer value, when we use it?

@@aldorrymiftakaruna1264 you should measure distance between shaft end for reference and it will use while doing refixing of coupling spacer.

Brother you are doing good job . keep it up. Can i contact you. I also working in fertilizer plant.

Thank you very much bro ❤

Bro can I get your number

@@arunpandian6914 7869724553

Bro reverse alignments video pls upload Bro.

Already uploaded bro. Kindly check it out.

sir please make a video on FACE TO FACE alinment ,please.....

I will do it. Sure but it will take sometimes. Please wait and stay tuned sir. Sorry for delay...

Sir,Is it necessary to put Radial and Axial Guage together at only 12'o clock position ?. if I fix Radial Guage at 12'o clock and Axial dial guage at 6'o clock will it help me with Rim and face formula method. Thank you

If you are doing practical alignment. and there is not provision to fix axial dial with same position. You can fix 6o clock position. Then Individually you can take readings for radial and axial dials. If you are using formula. Then we need to follow same procedure to obtain perfect values. Thank you....❤

@@rasetech Thank you sir

Which side should the clock be placed? placed on the pump side gives a different value. placed on the motor side gives a different value. very large number. looking forward to the answer

Its depends upon your convenient. Follow any one side. dont make things difficult. It will confuse you... Make the pump fixed machine always. and fix the dial clamps fixtures in the pump coupling. and Fix the dial indicators in Motor coupling. if It is large machine and motor having journal bearings. Please check Rim and Double axial Alignment method or reverse dial Indicating alignment. Dont use normal rim and face alignment.

@@rasetech thank. do you have any exact documentation about it. i want to understand more

@@Quy_Tran64 Very sorry I dont have any documents. I am giving this information from my working experience and knowledge. I think you can go through it with your equipment OEM manual to confirm the same. You will get exact reference from there.

Hlo sir 2 axial ka calculation bataye

hi Sir ,a very good video for me...i hv one question at measurement C...is it we measure from center of dial rim or only center of B bolts..tq

Measurement C is distance between motor Front foot and back foot bolt center. Its center of base bolts.

@@rasetech

Another question sir

Do we start the dial gauge from 12 o'clock to 6 o'clock...and if we do alternately it will giving different value...am I correct?

Yes It will remains same value but sign will change

How much pressure should be given to dial gauge before starting reading taking

You can give upto 4 to 5 mm

I dont understand about bar sag value? Please explain

Already expained cleared please go through it...❤

Hello sir, I request you to make video of making alignment and taking measurements and how you fit dial clamp in making horizontal moves.

Is bar sag value is common?

Bar sag is common... but bar sag values will be different...

Bar sag ye keya hota hai . Pleas make video

Thanks for your video.. Please see this Hindi version for more clarification...

th-cam.com/video/8xeIqVVPFN4/w-d-xo.html

Bro formula ethum use pannama vara reading ah ?÷2 pottu pannalaama..

Rim reading ku applicable bro but face reading ku not applicable bro.

Aana inga plant la formula yaarum use panrathu illa bro.. rim and face kum.. ÷2 than pottu panranga.. aana accurate ah varathu rompa time aagum

Nenga podura videos nalla helpfull ah iruku bro..

@@rajeshrajerajesh2691 formula use panni try pannunga time save

Ok bro

Bro gas turbines ah pathium video podunga bro..

Podalam bro konjam wait pannunga na one by one poduranga bro konjam time edukum kandippa poduranga bro

Romba thanks bro..

Sir ak problem he

Meaning of 12" clock and 6" clock

12 o clock means top position. 6 o clock means bottom position.

Please

Not enough explaination....for horizontal movement is very common sense....the problem is how to find the axial correct alignment

Aap ke sat bata karna he

Please sir this video sent me in Hindi

Hindi version also available

th-cam.com/video/8xeIqVVPFN4/w-d-xo.html

My friend your computation is wrong

1.0666-0.15=0.9166

Thanks for your comment... dear sir its not plus. Its -1.0666... kindly check F dial and R dial reading... that I have mentioned clearly... this is for your kind information...

சார் உங்கள் போன் நம்பர் வேண்டும்

Facebook page la chat pannalam mail id la contact pannalam. Number yen keakuringa sir... number venum na membership la join pannunga adhula number irukunga sir...

Even this 0.2666-0.15=0.1166

Don't teaching wrong..because all guy us expecting wright ur computation

Thanks for your comment... dear sir its not plus. Its -0.2666... kindly check F dial and R dial reading... that I have mentioned clearly... this is for your kind information...

Cant understand him use A American

Sir plz whatsap number

Nice

Thank you ❤

Please