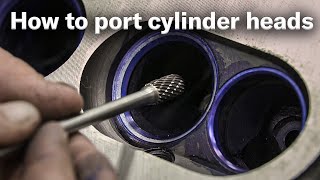

Subaru Heads. Porting, differences and discussion,

ฝัง

- เผยแพร่เมื่อ 25 ส.ค. 2024

- A detailed discussion about the Subaru EJ25 - B25 and D25 cylinder heads differences. Porting and polishing techniques. Performance modifications. Cams, manifolds and associated systems.

Feel free to leave comments below. I value your input and discussion. If you have seen anything that I have done wrong, please discuss. It will help me, and help the broader Subaru community. Thankyou.

Dont forget to click the like button.

I would love to see someone do this kind of video with some of the 2.0L heads

I really appreciate your video! I'm breathing B and D25 heads across many ej25's I've been working on, and you've added a lot of important details for me to marginally improve my game.

Hi Briam, absolutely loved this video.I Haven't found anything as informative on here.

Have you have any issues with valves sealing properly after you clamped them down to your block with the half inch head studs?

Some people have told me that I need to get my valve job done by a head place that can clamp the head down to replicate the same conditions. Im not sure if this was an isolated case of one person having a priblem and then the word spread or if it is a problem.

Really appreciate your help

Stuff a pair of dowels in the exhaust set up to make sure they match.

Very impressive video. You know much about the FB20 engine?

nice detailed video! I am about to go bigger with my D25 heads for my LGT wagon build.

Tanner Robinson

Thanks for watching.

_wish it was closer so i could just see it better because everything looks pretty similar from back here to me_

Great video, lots of detail. Did you pressurize the exhaust manifold and check for leaks after fab? I have a hell of a time keeping the v-band flanges (turbine and WG) from warping and causing exhaust leaks. Exhaust back pressure will always be higher than boost/intake and looses in turbine efficiency correlate directly to compressor efficiency loss. I have done a few of those long runner NA intakes and always get carried away removing crap. Typically end up having to make al plugs to fill holes resulting from removing EGR stuff. I pressurize, find, and seal any post weld leaks. Not fun to find and repair (weld fill) those leaks after its all in a car. D25 heads around 2006-2007 (USDM) got rid of the half moon seals. All the 08+ D25s I have seen don't have these seals. The #3 rear cam caps use bolts with precision machined shanks for aligning the caps over the heads, works well. The #1 and #2 journals on the cap bridge sucks for alignment. Only alignment is via the pins adjacent to the #1 journals. The #2 journals are aligned off the #1s, or basically have no provision for alignment. The id of the mounting holes on the cap bridge are crap. They are not designed as a point of alignment with the bolts like the #3 caps. The #2 journals tend to spread outward. This eliminates any oil clearance and can often be felt as resistance once everything is lubed and assembled. If I feel tight cams I can loosen the #2 bridge cap bolts and squeeze inward while spinning the cams, the resistance will go away. Not sure if this is a real problem but it is an issue I have observed on at least 4 sets of D25 heads, including one brand new set of heads. I noticed this cam journal misalignment issue while looking for root cause of cams that went flat; apparently due to poor lubrication (GSC S2).

albersondh

Thanks for the reply.

Yes. The manifold was tested for leaks. But not the V-bands themselves. And i know how difficult the V-bands are to weld correctly. Its very easy to let the heat build up in the band as you weld and that causes the distortuon as it cools after welding. I think my V-bands are good for the turbo and gate. I went extremely slowly while welding them. I know that one of the V-bands for the post-turbo exhaust leaks as it drips condensation at cold starts. But that was into alot thinner tubing. The headers are quite thick pipe (sch10 1.5" ss304) and that has better heat handling than thin exhaust tube. So its a little bit easier to weld straight.

Also good info about the cam caps. That is something i will pay attention to as the time comes to assemble.

posting in case your build isn't done yet/for people who might see this vid. From the reading that I've done it sounds like most of the exhaust runners should be left un-ported and only have the dog-legged runner cleaned up to help it flow the same at high lift. Also the bowls should be blended/opened up a little bit on the exhaust side to help low-lift flow across all of the ports. This is all hear-say, but going off of porting posts on nasioc where the heads were claimed to be flow-benched. Great work BTW! How did the intake valve seat job go? I'm having my ej207 head combustion chamber matched to fit my ej255 bottom end and they had a bit of water pooled up in them/surface rust by the time I was able to pull the motor out of my car. Also I'm doing a de-stroker build too! Manley +2mm rods and their high comp 99.75mm pistons :-D

ryan lewis

Hello and thanks for the comments.

Yes. I am by no means a cylinder head expert. And have heard many different theories. As i said in the video, I am only going from what i have been told, and what i guess to be good.

The valve seats were replaced with BeCu seats. A couple of the OEM seats had a wierd gap around thier OD. Almost like they were lifting from the counter bore in the head. So I decided to replace them. So they now have gold coloured Beryllium Copper seats.

Engine isnt together yet. Have had massive delays with the shop doing the CNC close decking. It was supposed to be returned back to me over 7 months ago. Have just been told the CNC work has been completed this weekend.

Since making this video, I have discovered that 2 of the intake valve seats need replacing. They are beginning to seperate from the valve seat counter-bore in the cylinder head. My suspicion is that perhaps some corroision is forming on the outer diameter of the valve seats. And this is forcing the seat away from the cylinder head.

I dont know the history of these hesds. They were hoven to me by an engine builder friend of mine. But it is evident that the engine they came suffered a rod bearing failure. As there is witness marks on the squish face of the head where the piston has contacted the head. This would have also potentially clipped valves. If the engine then sat for some time with those valves open/ not seating correctly then moisture and corroision could form. The affected valve seats are both intake and on the cylinder that had the rod bearing failure.

I am looking to go a copper alloy valve seat amd replace all of them. Maybe beryllium copper if i can get my hands on some.

Copper is the way to go. I think GSC makes a great set!

Tanner Robinson

I ended up getting a set of Tomie Be-Cu "Bery Rings" (Beryllium Copper)

They are being cut in at The Engine Shop in Canningvale as we speak.

Nice! I am finishing my heads up in the next day or 2. Only bc272 cams going in

Tanner Robinson

I like how you say only....

Are you doing any port work with them aswell?

I went down the shop yesterday and the Beryllium seats are cut into the head and installed.

Machine shop owner suggested i look into shim under bucket lifters. He said that it is alot easier to set the valve clearances. But i think i will try with the standard buckets first. I have a few engines worth of buckets to pick and choose from.

Bram Biesiekierski lol well I didn't have to machine the heads to fit the cams. I did some porting mostly cleaned up everything and port matched, +1mm valves fitted, bc springs and retainers. I am going to go with the shimless buckets too. Have heard horror stories of someone buying a shim loose especially in higher rpm applications.

Hi Bram, do you have much experience/exposure to the MY97-98 EJ20G heads?

Thomas Caruana

Not really. What is it you want to know?

Bram Biesiekierski I'm trying to work out the aftermarkert support in terms of valves, springs and cams. Very limited options from what I can see.

You will probably find more support from the Japanese tuner companies. And less from say USA etc. As those cars were very popular in the hieght of JDM tuning. But most of the japanese tuner outlets probably would have discontinued support for older models like that by now.

What’s the air injection all about... is that just for blowing out all the crap or something?

what sort of numbers does this beast make?

Fuji Wags

The air injection is a system Subaru use to help meet stricter emmisions targets. Subaru call it something like secondary air injection. And it was introduced around 2005/6 on the DOHC turbo models across the Subaru range. And possibly other models aswell.

The system comprises of an electrical pump, some solenoid valves, and the plumbing and passage ways into the cylinder head. The system is only active for a short time after initial startup. The system literally pumps air into the exhaust. I guess the extra air is used to neutralise the rich fuel mixtures needed during cold start???

The system is famous for expensive failures, especially on the early models. And would often require repacement of the solenoid valves and/or pump. And it is often by-passed in the aftermarket due to the cost of replacement from Subaru.

Unfotuantly the engine is not together yet. I have had a bad run with engine machine shops. Getting the CDB took nearly a year in this part of the world. And one shop performed a line hone on the case and forgot to tighhten the main bolts. I would like to be around 600whp once done.

@@BramBiesiekierski

Is that an Australian 20 cent piece?

@@wyattoutlaw2370 yes

Bram, did you get it together? Update?