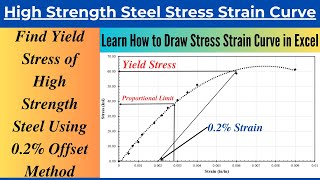

Stress-Strain Curve for Steel and Resulting Points of Interest

ฝัง

- เผยแพร่เมื่อ 13 ม.ค. 2025

- Uses a spreadsheet to organize data, make it physically meaningful, and plot it as Engineering Stress vs. Engineering Strain. Other calculations and points of interest are highlighted, including the Modulus of Elasticity, Yield Strength, Tensile Strength, Ductility, and Resilience.

Bro you just saved me, I have a project due and this is exactly what I needed.. 🙏🔥👌🏻

You are very welcome! Glad I could help.

you are amazing! u saved me! thank u so much and please keep making videos. u r brilliant

Thanks for the upload. But don't use eyeballing on the graph. For your strain axis, bring the minor smaller units, thus you'll have 0.002 displayed on your strain axis which makes the intersection of the parallel line to it much more accurate.

Thanks for the effort.

For .2% offset go to 10:20

Thanks!

this really helped thanks

Sir you just saved me 🔥🔥

how can i find the young's modulus from this graph? is it just the gradient of it by sketching the tangent line then showing the equation of it to get the y-intercept as well?

The Young's (elastic) modulus is simply the slope of the straight part of the graph. I show my method of estimation from about 8:20-10:20 in the video.

This video was very useful once i put it in 2 times speed

HI~

Where does the formula(young's modulus) come from?

where can I download datasheet? thanks

I did not understand how you got the yield strength, will appreciate if you explain it again

+miguel pico

It must be estimated where the stress-strain curve intersects a line

parallel to the elastic curve (with a slope of E) that starts at 0.2%. There is no formula to calculate it.

I hope this helps.

+Engineering and Design Solutions Thanks a lot!

What kind of steel do you use?

Hi Can you explain how i find the toughness from the graph?

+E.Ammar Ammar

Toughness is area under the curve. You can find it by

a) creating a grid and counting squares (my favorite)

b) assuming approximate shapes (such as a triangle for the elastic region and a rectangle for the plastic region)

c) assuming some equation and taking the integral (good luck with this one)

Sorry if you are disappointed and wanted a nice equation, but this is the best I can do. It's not math, it's materials.

Why this 0.2% yield strength becomes so important, i have also seen in many books they define it for 0.2%only??

+Mech E

0.2% is a generaly-accepted rule-of-thumb. There is no theoretical or analytical reason, it is just accepted practice so it can be compared from one material to the next, since they all behave differently.

I think it is just a convention. For any deformation in tensile area that has strain less than 0.002 (unit) will be considered to be in elastic zone, then we just draw a straight line parallel to elastic line through the point. The line cuts the curve at a point called Yield Point.

thank you so much ,you helped me to do my report

+zizo ahmed

You are very welcome!

How would you find area of PVC? is it still (diameter^2)* pi/4?

so the graph must be in psi vs in/in? what if mpa vs mm/mm?

Im struggling to find the modulus of elasticity and 0.2 offset

+ujek88

MPa vs in/in will work fine and will look the same, just a different vertical scale.

how do you find the diameter?

would you be able to figure out an exact value for the ultimate stress rather than just guessing on excel?

The ultimate stress is pretty well established here. It's yield strength that's estimated, and that's because there is not a definite, clear spot for many materials. Therefore, we use the 0.2% offset convention as is shown at about 10:20. I hope this helps.

how to find absolute and percentage uncertainties in the tensile strength result?

+Zeeke

There is not enough information here for that. Is this in comparison to some "accepted value" in a reference?

Engineering and Design Solutions not sure what you mean but if you have a stress strain graph ? shouldnt you be able to work out these values?

+Zeeke

When you mean "uncertainties", you have to have something to compare it to or some assumed uncertainties from the equipment, measuring, etc. None of these are provided in the problem, so I can't help that. That may be why you're having trouble, too. Are you trying to complete a lab that requires this calculation? You may want to find some "accepted" values for the materials you were testing. Matweb.com is a good place to find some.

isn't the lbf pounds per feet?? aren't you suppose to find in pounds per inch so you can find psi?

Sorry it took so long. Lbf = pounds force (as opposed to pounds mass, stupid US system), not pounds per foot, which would be lbs/ft.

What was the strain rate (e.g. inch/minute) for this data?

It was a problem from a book. The Strain rate was not given. Sorry!

THANK YOU!

There's a button for switch rows and columns.

It doesn't always work the way you want it to. You'd think after a couple of decades they could make it work better...

Excuse me,how can I know the coordinates of yield point?

The yield point is what I find from about 11:00 to 13:00 in the video. There is no formula - it is just the stress value where the 0.2% offset line crosses the data curve. It is always an approximation. If you want to enlarge your graph so you can be more precise, that's fine.

I hope this helped. Thanks for watching and commenting!

Howdy,

Great Video!

Is there a way to determine a more precise Proportional Limit from the data/graph?

Thanks

Yes, but I thought the video was long enough. I would set up a second set of data based on the first. The data would start at (0.2%, 0), then go in a straight line at the rate of the modulus calculated from the first set, using enough points to intersect (technically, you would only need one other point). Finally, I would add this data set to the data of the graph so they would overlap. It's actually more of a spreadsheet exercise.

Thanks for posting!

Right on, thanks for the great response!!

THANK YOU SO SO MUCH.

Glad it helped! Thanks for watching and commenting!

I thought stress was in N/m^2

That's the metric system, this is the imperial system that america uses

Yeah, psi = pounds / in^2 . We're a bit set in our ways over here in the US. Sorry about that.

Hey, do you happen to know what all of my units should be? I'm doing it in metric. My professor said that most of them are Mega Pascals (MPa), but I don't know what to use for my ductility. Thanks!

Thankfully, ductility is a ratio of length to length, so the units cancel out. It would be the same in US or SI units.

N/m^2 is also Pa

for some reason i cant full screen the video... thanks though

So you don't actually solve for the 2% offset by finding where the two lines intersect. You're just guessing by looking at the graph its self. No offense but this unprofessional. You should use a graphing calculator to find the intersection between the Stress/Strain Curve and the 2% Offset Curve.

I started watching this hoping you would show us how to extend the 2% Offfset line past the Stress/Strain Curve. Using linear interpolation or something like that. Instead you just pick a number on the graph and call that the Yield Point.

Yes, you do "find" it, just by the method you are deriding. However, if you know the equation of the curve, sure, you can find it by the two equations equal to each other and solving for the unknown. But the problem never finds the equation of the curve. Why? It's not based on some math formula, it's data taken from a real-world situation. You're expecting this data to fall *perfectly* into some nth-order equation that can be analyzed perfectly. It is no such thing. Would you expect a commute to work or school to take *exactly* the same time *every* trip? It doesn't happen that way.

Could we model the data using Fourier transforms and such? Yes, we could. There are a few problems:

1. Complexity. This would take significant effort, usually beyond the capabilities of the practitioner. Program a computer? Sure. Go for it.

2. After that effort, it still would have error, maybe worse than the "by eye" method.*

3. You would be basing a lot of effort on a single sample.

4. If you used a larger population (more samples), you would lose some of the applications of the test to the specific sample.

5. The 0.2% method is a rule-of-thumb used by decades of materials scientists and engineers. It is not a magical, "aha! there it is!" place. It is used, in part, because that's what's been done before, like a tradition, and in part because it is a common way to compare materials, even when its applicability could be questioned. Different grains in the material will "yield" at different applied stresses, so there is no spot where the *entire* sample itself yields.

* "Error" implies that there really is a very specific true answer to compare to. At best, you'll have an average with spread above and below it. More likely, in the literature, you'll find that materials producers may have an "accepted" value that's less than the mean so that they aren't held accountable to too high a standard.

After all was said and done, you would expend a lot of effort to achieve effectively the same results as the "by eye" method to determine a value that, itself should be considered with skepticism. "Yield" is not a destination, it's more part of a path that occurs "around mile marker such-and-such". It's not "unprofessional", it's simply less analytical that you'd like, but practical. Welcome to engineering.

Forgive me, I'm a first year student in robotics. I didn't know that the .2% Offset wasn't a standard but just a "we-think-this-works" hand-me-down. I thought it would make it easier to find on a spread sheet if you could use Linear (Extrapolation) to extend the .2% Curve past the Sample Curve and find the intersection. Considering all you have to do is just plug in the numbers once you have the equations in the spread sheet. You could be a lot more accurate AND save time when compared to just "eye-balling" it. Then use the same procedure for multiple samples, maybe take an average of each? I don't think you can ever be as accurate as the math, no matter how hard you stare at the graph. Thats my take on it, anyway.

I understand that each grain basically has its own individual Yield Point. It would be too expensive and time consuming to try and find a .002% Offset "range" of a given material.

I would certainly expect that from an aerospace company, however. You wouldn't want to die because the plane you were flying in fell out of the sky, all because the wings couldn't take a little turbulence! Would you?

It just seemed a little unprofessional to me because other people's videos use some sort of mathematical calculation for their .2% Offset, I just can't follow their methods because they only work for their particular data.

You're still assuming there's some "equation" on the spreadsheet that reflects the data. Here's an idea to create an equation: take the point closest to the 0.2% offset, then the one before it and the one after it. Make a 2nd-order equation based on just those three points, then see where it intersects the 0.2% line.

To make it more interesting, use the "by eye" method first, then compare and see what your error is. THEN compare to an "accepted" value (or two) and consider all values critically.

Understand that this is a bit dated of a conversation but wanted to chime in. Not difficult at all to calculate the 0.2% offset with a bit more "certainty". Simply grab the data for strain associated with the linear portion and add 0.002 to it. Then right click on the graph, select add data, new, then select the regular stress for the linear portion and your new strains with the 0.002 added to them. Add a trendline to extend past the curve and its a bit less temperamental then simply snapping a line. Hope this helps.

I would add that as the originator of the post says this isn't a hill to die on. Just a helpful number to have. We pack engineering full of ways to simplify things, makes our life doable and practical.

i love you.

Wow, that's new, but I hope the video helped as well! Good luck in your studies!

اللي من اصعب جامعة بالعالم يضغط لايك

R u explaining to ur legs or what ☻