Cylinder Head Flow Test on a DIY Flow Bench Kit

ฝัง

- เผยแพร่เมื่อ 19 พ.ย. 2024

- For more information visit www.flowperformance.com

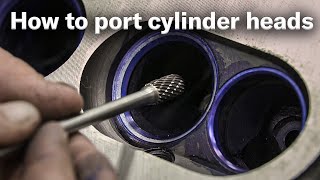

An internal combustion engine cylinder head is flow tested on a Flow Performance precision electronic flow bench.

Flow bench testing cylinder head using the Flow Performance flow bench kit FP2.0BS. The FP2.0BS is very well suited as a cylinder head flow bench, but it is a flow bench kit that can flow test many other automotive items like intake manifolds, exhaust manifolds, carburetors, mufflers, air filters and much more.

Flow Performance flow bench kits employ the power of a personal computer to give the operator instant flow rate readings while flow testing. The software that is included with the flow bench kit is versatile and can connect with Microsoft Excel ® for custom flow data processing, storage and graphics. The Flow Performance software works well as a flow bench software too.

A cylinder bore adapter is used to simulate the actual cylinder that the cylinder head will be bolted to during actual use. By sizing the cylinder adapter to the same diameter as the actual cylinder, the flow test results will best simulate the effects on flow that the actual cylinder will have on the flow of the cylinder head. Cylinder bore adapters are available form, flow performance.

Cylinder head flow bench tests are conducted at a certain test pressure, or vacuum, depending on whether the intake or exhaust port is being flow tested. Flow bench testing cylinder heads are usually tested at 28” of water pressure, or about 1 PSI. Other common test pressures are 10” of water, and 25” of water. The flow bench cylinder head test in this video will be using a shop vacuum to produce the test pressure and air flow through the cylinder head. The test pressure from the shop vacuum will not be regulated to a specific test pressure. It will just be left to produce as much pressure as it can, and the Flow Performance electronics and software will estimate the flow rates to the desired test pressure. In this video, it will be estimated to 28” of water.

Before the flow bench operator starts the cylinder head flow bench, a clay radius will be installed to the intake port entry, or and extension pipe installed to the exhaust port exit. The clay radius on the intake entry will help simulate the effect of the intake manifold, and the exhaust extension can simulate the effect of the exhaust header being bolted to the head. In most cases, flow rates will be lower without these items installed.

The flow bench operator will flow test the cylinder head with the intake, or exhaust valve, set at different heights. The valve heights are usually set in increments of .1 inches or .05 inches, to the maximum valve lift or height. At each valve lift, or height, setting, the operator will record the flow rate for that valve setting.

![กี่หมื่นฟ้า | Your Sky Series EP.1 [1/4]](http://i.ytimg.com/vi/vLGjxFL6U_I/mqdefault.jpg)