The Ingenious Mechanism In a Grand Piano | 3D Printed

ฝัง

- เผยแพร่เมื่อ 22 ก.ย. 2021

- Support my latest campaign, Grand Piano, launches on 8th February 2022 with 72hrs Earlybird on the first 3 days: [ mmf.io/mechgrandpianocfxex ]

Grab the 5% discount code here [ MECHYT5 ]

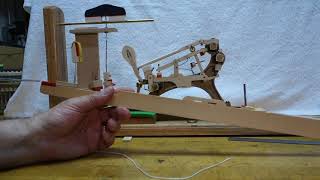

Hidden in every Grand Piano is an amazing mechanism that is activated with every key stroke that allows rapid repetition of key strokes and a responsive yet sensitive sound production.

This 3D printed model is meant to showcase the mechanical aspect of the piano action model. The strings are replaced with steel rods for a much simpler acoustic construction and therefore it sounds more like a xylophone rather than a piano. - วิทยาศาสตร์และเทคโนโลยี

With all the mechanical clocks you made now i am imagining you combining the clock mechanism with a date function and a music box 🤩

Haha yes! A chiming mechanical clock is in the pipeline :)

How about a piano clock that only displays the time if you play the right tune

So impressed by the attention to detail. This will make an excellent teaching tool for anyone who wonders what's under the hood of a grand. Once you release the printable models I may make one, assuming I can find or make the metal parts.

Bravo and thanks!

Perfect gift for my music teacher

The little keys swinging during the build is beautiful. Excellent work.

The nostalgia this video evokes for me.... My dad was a piano restorer/tuner/dealer and we had a little model of a piano action in the showroom. I remember playing with it so much as a kid fascinated by how the movements translated to the strings. That was fun.

edit: if you need to ask my dad any questions about piano actions i can pass them on ;)

This is why I love engineering.

I would LOVE TO see people start using 3D printing to restore their pianos. Piano parts can be so freakin expensive. With time, maybe we’ll even begin to see filament with different densities to really fine tune the sounds they produce.

I support this

Actually this sound amazing. I don't know a out the technical difficulties that might occur, but this is ultimate right to repair since no one can claim the piano and still some do

I think its the future. While sure so old piano people might not like it because "pianos use wood what is this 21st century computer made stuff" most people would be excited to learn the $1000 hammer replacement maybe only cost $100 with 3d printed parts

@@superspooky4580 its not so much that 3d printing is from the 21st centory but that wood has excellent audio properties. But eh 1 plastic hammer can't hurt.

@@Ramog1000 True, one might be able to add weight to a plastic hammer to give it similar feel to the other keys. Not sure how much more or less flex would occur with a plastic hammer...

Understanding things by building them, my preferred way! Great new Project.

As a formal piano production manager for Klavins Instruments and today independant technician for the best workshop of Europe, I always dreamed to do exactly this. Dude this is absolutly amazing. Thank you to be so creative. A grand PianoToy, is a genius idea

Switch the rubber bands on the far side to fishing line. On the other side make it a solid connection. It should sound better.

You should attach the metal "strings" so that they are supported at their vibrational nodes, eg. 1/4 from end, so they would vibrate naturally when key is pressed. Otherwise the sound is damped.

beautifully done! I have always been curious about how Pianos work! Thank you!

Imagine an entire 3d printed piano...

That would be cool.

beautiful as always

I just love this build, excellent work!

As a piano tech, I can really appreciate this. Very good!

Bravo! Thanks for your dedication

Absolutely love this!

I love the minute repeater mimic at the end

You are now my favorite youtuber!

Yes. I subscribed to have a look of a full 3d-printed grand piano

its gorgeous.

Wow...erst jetzt kapiere ich, wie diese Mechanik mit dem Anschlag funktioniert! Geniale Arbeit von dir 👍

Beautiful!

Can I please get the STL files? I am actually working on a small model grand piano and this would be PERFECT :)

Good idea! I think there will be more grateful viewers if you give the file.

It should be on his my mini factory page

You might have to pay for it though

@@quarterpie5338 Or thingiverse? so you dont have to pay for it :)

@@filippus_ why should you not have to pay for it? It's his design that he spent the time to make, let him reap the rewards

@@filippus_ I think you have overestimated the youtube payback rate by a factor of at least 10.

And you said this 2 days ago, when it likely had far less views than it has right now, so you more than likely overestimate the youtube payback rate by a factor of 20 or more.

The video probably took *at least* several hours to edit together, and *at least* several hours to capture enough footage.

By itself, the approximately $400 usd he has earned on his 78 thousand views (at the time of my viewing) probably covers the production costs of the video. (He also had to already own a camera and computer for the editing).

On top of that, there is the cost of the design work on the piano parts. (This video contains zero part fit failures or part adjustments, which means this design has gone through many many many design iterations to get to this point).

I honestly wouldn't be surprised if there was a month or more full time design effort gone into this to get it to the point it is at right now. This includes printing time.

I don't know about you, but even $4000 starts to run a little thin for payback for the design effort alone (remember, this is pre-tax dollars we are talking about)

Then we have to add materials cost, each of these parts was 3d printed, some of them would have come out perfectly the first time, but chances are REALLY high that basically none of them came out right the first time, and the nature of the mechanism is such that if 1 part needed minor adjustments, that literally every part that touched it needed to be updated to take into account the new geometry, so each single-part change, would likely amount to upto 3 additional part changes to fit with the new part.

So there is additional costs for reprinting plastic.

So, taking all of the above, and the fact that at best he probably only earned around $400 off the video (so far, he might hit the algorithm and go bananas but no promises, he might actually hit your $4k amount at 1 million views!, which is far from guaranteed), and you want him to just give it away totally free?

Absolutely fantastic work once again.

I myself was shocked as the author used a 3D printer.

That is nice and a lot of work. Bravo!!!!!

Nice touch with the minute repeater at the end ;)

This is fantastic!

MAGNIFIQUE - Bravo

I love how he just ends up playing 7:52 like a minute repeater near the end

Super nice!

I love this hammers

I agree. That is so satisfyingly to see an inside view of this.

Hey, I think the hammer and dampers are unusually felt lined. I wonder if that might help some of the noise issues you described here.

Damn now I want to make a 3d printed electric piano

Cool! Now I can build my own piano.

Also, please release the files! I'll gladly pay for them. I want to print this and put it on my baby grand piano! :D

Sure! I’ll release them once I’ve completed the assembly guide

@@mechanistic3d Any update? Again; glad to pay for them.

@@Prashanthkannan1 Same !

I love this, perhaps some of the joints could be replaced with flextures to reduce some of the clicking noises (I suspect lots of the clicking is the open-nature of the mechanism, and more or less unavoidable for a device designed to display the brilliance of the mechanism!)

Can kind of see where old typewriters got the idea from in some ways too. But then they also add a ribbon and carriage advance to each keypress as well.

Super cool I wanna make one

Nice had this planned for so long xd

Cool stuff!

I need those STLs.

Bonjour. Très bonne vidéo. Merci.

Mechanistic: "Mary had a little lamb... …see a lamb at school"

Me: wtf

Would it be possible to build a full piano with this?

Nice. Will you be releasing the STL files?

Awesome work you did here.

If I may humbly make a suggestion for the next version : You should try to use Guitar string instead of metal rod → cheaper than steel rod and will sound more like a piano than a xylophone.

For a whole piano, the length of strings will be difficult to handle with only 3D printed parts, but with a very simple wood enclosure, (U shaped) may do the work.

Looking forward you nexts videos

something to try: add softish metal tips (brass or aluminum ?) to the hammer so that more of the energy ends up in the vibrating rods.

The scope of the video seemed geared towards mechanics not transducing waveforms from one medium to another.

Excellent work, here. Now, I must note that for the repetition lever, I believe that as the wippen is lifted and the jack is rotated forward after contacting the letoff button, it is supposed (some simulations I have seen like on Algodoo missed this) to press into the inner surface of the end of the repetition lever, arresting its motion after it has already been compressed a bit (the tip of the repetition lever not contacting the drop screw yet), then on the release of the key, which would move the jack away, the repetition lever spring pushes the lever up a bit to receive the hammer knuckle earlier or push it and hence the hammer up a bit, allowing the tip of the jack to pass back under the knuckle more quickly or without having to release the key by as much, hence increasing repetition rate. Maybe you did try to implement this behaviour, whereby it just needs to be tuned per th-cam.com/video/O5q7OxnHkkM/w-d-xo.html which covers the adjustment of the repetition lever spring.

Heh, and you won't get away with sneaking that minute repeater chime in there. What's the significance of 7:52, here?

Thanks for the detailed explanation! I was still trying to figure out the purpose of slightly rotating the repetition lever, I initially thought that it was meant to to provide a slight clearance between the knuckle to the repetition lever when the key is fully pressed so that the back check catches onto the hammer instead of having it bouncing off the repetition lever and potentially re-striking the string. but now it makes more sense! Ill try to tune it and try the rapid keystroke.

Thanks!

now a full keyboard :P

Now make a fully 3d printed piano

I am keyboard player.. and I wanted to have portable action keys for practise and fun play... this could be great .... but need full range 81 keys... or at least 61... and better sound from this.. metal cymbals sound... :) but overall idea is great... I could buy this stls...

Lovely♡

Great video, is there any source for the stl?

damn.. it's a lot more complicated than i thought...

Thumbs up for genius proven.

Can you try the vertical music box like Montblanc high artistry great wall the mechanical is very complicated and non article about it mechanic so far

Make a full sized piano pls

Now people can understand why they are so expensive

Nice

And to think that this insanity was designed in the early 1700s… O_O

How much weight needs to be applied to the keys?

Music by Beethoven - Sonatina No 2 in F Major.

Wow! How did you print those metal parts?

looks like a hybrid between grand and upright, right?

Where can I buy the pieces to be assembled?

(I don't speak English, I hope I haven't made any grammatical errors)

Woow bro ✌😊

I thought this video would end in Hotline Miami murder

Cool

Seeing you building only 5 notes i understand the price of a grand piano

Piano lore

rods are probably way easier but make it sound like more like a xylophone to me. Great work though, how long did it take to 3d model it?

Yeah I’ve tried using guitar strings but without a sufficiently large acoustic chamber, they sounded like an electric guitar without any amplifier. I’m trying out different rods material as well as geometry to hopefully get a slightly better sounding xylophone out of it 😂. Took me about a week to study and understand the mechanics and 2 weeks of modelling including a couple of iterations.

Just 83 more keys to go.

Play this at 2x speed: insert song somebody that i used to know

Good idea

any plans on selling the STLs ?

Gonna do the entire piano, right?

i see its complicated so it can quickly pull away from the bar letting it ring

Were are the link of the 3d file?

What kind of printer do you use?

How to get stl or blueprint to print myself?

*bobby duke arts voice* "I want thayut"

Ok that settles it. I'm investing in a 3D printer.

Oh that's embarrassing. I still don't know how it works. Anyway, I got to go now. The "short bus" is picking me up at 2:30 :O\

the files pleaseee, I like this project ♡

This look really cool but awfully difficult to assemble

How did you get each key to have a different pitch? All the rods look about the same to me, and my understanding of mechanics is meager at best.

If you look at 4:22 the length is different for each rod.

@@wanderyak5749 oh, I see. Thanks for pointing that out!

can you share 3d models?

How I can buy this parts?

*Inventor:* _"I need you to make a copy of this..."_

*Replicator:* _"Okay, I'll have it done by tomorrow."_

*Inventor:* _"... like 88 times."_

*Replicator:* _"Fuck this shit! Deal's off!"_

🔥💕😍👍

Please share the STL at least!

What kind of steel rod?

I used 3mm diameter hardened stainless steel rods but it works with pretty much any kind of steel rods including brass and copper tubes of similar diameter

Is the file downloadable? Free? Or u selling?

if i give you an idea to make in the comments would you accept the challange and make it?

Let’s hear it :)

@@mechanistic3d1: okay can you try something that works on weights? 2: mayby something that walkes around using gears, in my head i had like a dinosaur but i think something with 4 legs will be easier.

3: coocooks clock idk how to spell, that one clock with a bird that makes a sound using a flute that changes tone by tilting

Good stuff... Here's a comment for an algorithm boost man...

Thanks a lot, really appreciate it 🙏🏻!

Hanzhen harmonic drive gear , over 30 years experience , robot gear , joint gear reducer

Just stop teasing us already and tell us where we can buy the files LOL

How do you "tune" the piano?

Now there are special applications that can help you do this.

@@AkopianDIY But in a real piano, each note has springs of different length. They are tuned by stretching them. In you model, all the metal rods are of the same length, and they are solid...

But i like the typewriter-like sound

Please make the rest of the octave, until you have 88 keys