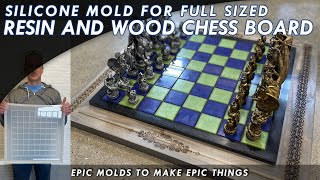

How To Make Epoxy Resin Cutting Boards - DIY River Resin Charcuterie Boards + Big Time Saving Molds

ฝัง

- เผยแพร่เมื่อ 5 มิ.ย. 2024

- Shop Our Molds @ CraftedElements.com

-----------------------------------------------------------------------------------------

A comprehensive video showing how to create your own epoxy resin cutting board, from raw live edge wood, to finished product.

Looking to get started in woodworking and epoxy resin? Follow along while we complete 19 steps to create a beautiful 24x12" charcuterie board using wormy maple and blue epoxy resin. These 'river table' like serving boards are awesome, satisfying projects and are currently in demand as high end gifts, especially during the holidays. Creating something so beautiful has never been more fun!

Plus, we reveal time saving techniques using pre-made silicone or HDPE forms that greatly reduce the production time and stress involved in making these wood and resin boards.

Our silicone molds are the last epoxy resin charcuterie board molds you will ever need. Created just for makers, resin artists and wood workers, these time saving flexible yet durable silicone molds significantly cut down on the setup and demolding time usually involved with other board molds. These molds are superior to wood and tuck tape, and HDPE molds because:

-They never need assembled, or disassembled. Saving huge amounts of time.

-The strength and flexibility of the molds allows you to insert and remove pieces of wood easily.

-The corners and edges never need sealed.

-The wood stays in place, tight in the mold, if you cut it 1/16" larger than the width of the mold. Preventing the need for clamps or weights.

-The mold is heat resistant (within reason!), and wont damage when you are popping epoxy bubbles with a torch or heat gun.

-The molds are reusable. How many times we are currently unsure of, but many of our molds have made 40+ boards and still look new.

-Like HDPE, epoxy does not stick to silicone. However in some cases where the epoxy hasn't fully set (and is still mildly tacky) it can be harder to remove, and potentially create pits or small tears inside the mold when your piece is pulled out. Thus, we recommend the use of mold release spray before each pour to increase the life of your mold. This spray is readily available from Amazon.

Recommended Product Links & Resources

*********************************************************

Molds: Crafted Elements - craftedelements.com

Router Templates: Crafted Elements - craftedelements.com/collectio...

Router Sled: Crafted Elements - craftedelements.com/routersled

------------------------------------------------------------------------------------------------

Epoxy Resin: @TotalBoat - craftedelements.com/a/totalboat

Makerpoxy (For Pours Under 1/2") - craftedelements.com/a/totalbo...

Thickset (For Pours Under 1.25") - craftedelements.com/a/totalbo...

Thickset Fathom (For Pours Up To 3" & River Tables) - craftedelements.com/a/totalbo...

------------------------------------------------------------------------------------------------

Pigments: Black Diamond - craftedelements.com/a/blackdi...

------------------------------------------------------------------------------------------------

Mold Release Option 1: MG Chemicals 8329 - craftedelements.com/a/mg8329

Mold Release Option 2: Mann Ease Release 200 - craftedelements.com/a/mann200

Bark Removal Knife: Beavercraft Draw Knife - craftedelements.com/a/drawknife

1/4" Flush Trim Bit: Amana 46297 - craftedelements.com/a/amana46297

1/4" Plunge Template Bit: Amana 47224-S - craftedelements.com/a/amana47...

3/8" Plunge Template Bit: Amana 45475-S - craftedelements.com/a/amana45...

1/2" Plunge Template Bit: Amana 45460-S - craftedelements.com/a/amana45...

2.5" Slab Flattening Bit: Spe Tool 2.5" - craftedelements.com/a/spetool...

------------------------------------------------------------------------------------------------ - แนวปฏิบัติและการใช้ชีวิต

The table saw push stick is meant to push the piece between the blade and the guide wall. That's the piece that will get shot back at you. It's not meant to push the piece on the open side. That piece won't get kicked back. Be careful of making a missile. The board came out very nice. The mold was a great idea.

Yes, clearly my saw technique needs some work in this video. I think at the moment this video is almost 2 years old and I have learned my lesson.

@@CraftedElements Hopefully not the hard way. Thanks again for sharing the process.

Its so beautiful!

Beautifully created, thanks for sharing your work with us 🙏🏼

Thanks for watching!

Excellent! Thanks

I love how you explain all the things that can be wrong and you show me all the ways I can fix the problems and you do a great everything is beautiful. Thank you Sherry Mortensen

Glad to help. Thanks for sayign that.

Thank you for your service

Thank you!

Great video, best at explaining each step. Thanks for showing how to debark and calculating the resin amount. I learnt so much about how to prep the wood and the levelling process. ❤

That's what we're here for!

Thank you very much learn a lot from the video. Great job.

Really enjoyed your video. As other have said, I appreciate the real time for each step. Hope to see more videos from you.

Thanks for saying that Bill!

Great video - just got my silicone mold today. Thanks

Awesome! Thanks Scott for your business and faith in our products.

GREAT video; best I've seen on these boards! And I love the fact you are doing each step in real time; not sped up. Thank you!

You're very welcome! Thanks for those comments.

Great videos , I learned so much . I am new to the epoxy game but with your videos I will have no problem . Great Products , fantastic molds and Templates

Awesome, thank you!

Great video, very helpful thank you.

Glad it was helpful!

You're my new go to guy for resin. I've been wood working a long time but just now starting to play around with resin. Thanks for all the info!

Well shucks thanks for saying so!

Love your presentation style. Very much a natural in front of the camera, and not apparently scripted. And the board, BEAUTIFUL! Very well done.

Thanks for saying that! In reality all these videos are NOT scripted, but I do often do 4 or 5 takes and have to edit together to find the best ones!

Awesome video. Answered every question I had.

Glad it was helpful!

THIS is the best, most complete video on River resin tables EVER -- of all that I have seen as yet. Thanks so much for doing this! 🏆

You are welcome. We actually have a new, complete 10 part series coming out where we go through each step extensively.

Thank you for the video. I have purchased one of your molds, and I can't wait to receive it.

Awesome! So glad the video helped you.

The best video teaching us how to work with epoxy

Wow, thanks! That means a lot!

fantastic video thanks!!

You're welcome!

Very helpful video. Especially where to start with what grit and end. Learned something new. Appreciate your time making the video.

You are most welcome. We have an entire modern series on this process, which much better filming here : th-cam.com/video/0KbBI2LQ0X4/w-d-xo.html

Well done Shaun.

Thanks! Much appreciated. Hope it helped. You likely want to see one of our newer updated videos, they are more thorough -> th-cam.com/users/CraftedElements

I follow you from Egypt I also work in resin You are creative and I learn from you, thank you❤❤

Awesome! Thank you!

Bravo. Awesome video.

Thank you very much!

Very nice project. I really like your silicone molds too, I might be interested in getting one or two in the near future.

We are always available at CraftedElements.com

This is great.

Great tutorial

Glad you think so!

great tutoriol thank you 👍👍

You are welcome!

Just checked out mold and template shop LOVE IT will be ordering THX 👍

Awesome! Thanks Jaime

Very nice Thx@

I do like your products. Hope one day I'll get better

very nice

Thanks

Can I make an epoxy board without having a planer but doing the sanding only?

Ty

You are welcome

I have to do one....! 🤗💕

You will love the challenge. It can become an addictive hobby, and even a side business for some.

It would be awesome to be able to purchase wood pieces that match your molds for those of us who do not have access to all the woodworking tools involved to make these, but for those who love resin work !

That's a great idea! Will take note.

Find a quality used miter saw, learn to use it safely, and cut what ever size you need. Or make friends with a local woodworker who will cut things for you for a small fee.

One teensy piece of advice; when pouring from a container with an offset neck like the larger resin bottle shown, always pour with the neck uppermost. This allows the air to leak in to the container evenly and prevents the “glugging” effect, giving much more precise control. Seems more awkward at first, but much easier in the event. As for bonding of pre-sealed edges; that’s down to timing. If you wait too long and allow the edges to cure, you will need to rough them up to create a mechanical bond, BUT if you pour before the edges are fully cured, the pour will form a chemical bond with the original edge that is full strength. The latter gives the best of both worlds. Finally, CA glue works well to fill pinholes almost instantly as you are sanding, especially if combined with an accelerator. You can even get black CA glue for this purpose. Larger pinholes can be filled with bicarb-soda powder, then hit with CA glue for rock hard filler.

Re: the pouring it totally makes sense, and definitely something I tend to just do out of habit. Regarding the pre-sealing of edges, while I agree that it would need to be not fully cured, or sanded, the brushed on epoxy still will not penetrate the wood as deep as it would vs. it being poured. It's basic physics, the weight and pressure of the epoxy (a full 2" pour) is going to force the epoxy deeper into the wood in general. As for the CA glue filling, its definitely something we do now that we didn't when this video is made, and we do cover it in our new video series (yet to be released but will be out soon!). Thanks so much for the thorough comments.

We just made a board using this mold and it’s awesome! About to sand and add handles to make it a tray. Next we’ll be trying the round one! Great video and thanks for sharing ✌️💚

You are most welcome, make sure you tag your creations with our Instagram tag so we can share them with our followers!

Excellent video. Ideas about when the molds will be back in stock?

June 1 is the big restock date currently!

Thanks for your time and great video. It’s extremely time consuming chasing out these hole’s. Do you normally clean out ever wormhole?

Not every one, just ones that appear to be brittle / damaged etc. You dont want pieces of your board falling apart.

Great informative video! I noticed you were using many similar tools to what I have in my shop. One set up that caught my eye was your router mounted to your table saw. Do you have a set up video on that?

I dont have a video on this, no. But its just a standard Mastercraft router table, that magically fit into the void that was already in the table saw. Kind of weird, it sort of just worked!

@@CraftedElements that’s awesome!! Makes it nice and convenient! I’ll see what I can find. Cheers!

informative video, Thank you. Is this board Food Safe. It's always a concern here in SA

It's dependant on the epoxy resin used, some are food rated, some are not.

I wanted to say I love all your videos I have learned so much. Question though when you are pouring resin you stop pouring when?? At the very very top?? Or 1/4in? Also what do you wash your measuring cups out with??

Either. You can leave space if you dont want to fill the mold and make a thick piece, or you could fill to the top of the mold. If you are using wood in the mold, then logically you wouldn't fill past the height of the wood. We do not wash measuring ups. The epoxy hardens in them. Often you can peel the epoxy out (if the measuring cup is plastic or silicone). If you cant, its just garbage.

Just ordered one your guys's molds, I started to cheap out but had a feeling I'd regret it lol, looking forward to receiving it

You will love it! Just make sure you use a mold release and you'll get a lot of use out of it.

@@CraftedElements you bet, I ordered the MG chemicals non-epoxy mold release, that was linked in 731 Woodworks last video

So just regular soap and water to clean between uses?

@@stephenpalazzi720 Yes indeed!

that was great! You've read it before, but I love the real time aspect, not super sped up. Minor question: how does the resin effect the blades of the planer? does it dull them faster or do you need to reduce the speed compared to maple or walnut? thanks!

To be honest I don't really know the answer. I almost always use the planer with resin + wood combination pieces, and we dont make a lot of them here because we are way to busy making and shipping molds. Im sorry!

I'm not running it through my planer

Made it to 11:49 and just noticed the Stern Pinball sweatshirt. My people!

Haha! Nice. Yeah I have a 'lil arcade in my basement. :-)

Do you not use the pencil marks to ensure proper sanding?

Will wood finish works well with epoxy?

Shawn...

When are you going to have more of the molds that are out of stock available?

It's going to be roughly 2 months or less for the out of stock items.

question: if you do have pinholes, is that something you would see in the first grit of sanding? also, say i find those pinholes at the end of sanding, then put more resin in there, does this mean i have to sand the entire side of that board from the beginning grits all the way up the grits or just with the last grit i was using?

Yes, totally you would see this (perhaps even before sanding). Once you do a basic sand, blow them out with compressed air then do a top coat / flood coat of epoxy to fill them if there are alot of them. If just small patches, apply epoxy in those areas (putty knife to flatten), let set, then sand again.

Hi like your videos. Can you please advise me, when I sand my resin it does not come out like glass. Am I supposed to put the oils on it for that to happen>

It depends on the mold you are using. Some of our molds are matte (dull) some are polished/shiny. You can always do a high grit sanding of a dull piece and then top coat / flood coat with resin to make it shiny/polished.

So do you have to use any mold release on the mold. Thanks

Yes, you definitely do: craftedelements.com/moldinstructions

Do you ever put screws in the edges of the raw to help stronger joints

Is there a way that those containers that the epoxy resin was mixed in be cleaned for reuse ?

It is possible, but the containers are very thin, they crack easily, so we typically don't reuse them.

Love the video! What temperature was the shop when you poured it? And what temp do you leave the shop at while the epoxy is curing? I recently just did my first pour and I’m wondering if I should have turned up the heat a little bit, I did the initial pour at 10’C!

Thank you!

Hey Ty! The shop is 19 degrees Celsius in general. I would do it above 15 degrees for sure!

@@CraftedElements alright I’ll go crank up the heat then! Haha thank you so much for the fast reply! I want to get the basics down so it makes it a little easier on me! Thank you once again! 👍🏽

@@Bergs9317 When i do my pour, I make sure the ambient temperature is no higher than 17 deg celcius. I use the same epoxy as Crafted Elements.

About how long does it take you to sand up to 220 as shown in your video?

U don't have to pour a mold release in that form?

Great job Chief. Quick question. Any idea why while poring the epoxy it would start to smoke? We did two pores totaling 2”, 12hrs apart. On the 3rd poor we did the quick set thinking that we only had 3/4 left to pore so it would be ok. Width was long, I’m thinking that’s the reason but not sure. Any idea?

Yup! You need to use an epoxy rated for the pour height (or volume, really) of what you are doing. A quick set epoxy at 3/4" is most definitely going to get too hot, bubble, smoke, curl and effectively ruin your piece.

What types of wood will work for these boards? Being in northern Alberta my stores have limited selection

Generally any kiln dried hardwood. Maple, oak, walnut, ash, poplar, etc.

Great video! I'm new to this and considering on start doing this as a hobby. Just a quick question, what brand is the casting resin you used for this project.

We highly recommend @TotalBoat Thickset + Thickset Fathom

Hey, what’s the formula you use to determine how much epoxy you need?

Here you go: www.totalboat.com/epoxy-calculator/

Olá poderia ATIVAR as LEGENDApara PORTUGUES em Sua Configurações no seu You Tub Obrigado....

If there's any resin left over how do you dispose of it???

Where can I find live edges? I’ve been looking and see that they are pretty expensive. Is that usually how it goes?

I guess it's relative. I don't know what's considered expensive to you. For a piece of live edge maple or black walnut, average serving board size, you should be able to get a 1-2" piece for between $20-$40. Check Craiglist, Ebay or Facebook marketplace. Search "live edge wood".

Have you ever tried to use this board as a stand for hot items such as a hot saucepan or pan and what could be a max temperature?

You wouldn't want to put a hot pan on epoxy resin (which is plastic) it would melt.

Maybe just use it as a charcuterie board for searching snacks

Is there a wait time for running it through the planer or just after demolding?

You want to make sure its hard enough. I normally wait an extra day to plane my item after demolding.

Do u have to flatten one side of the board before running it through a planner

Typically when using a mold with wood and resin, the bottom of your piece is flat (enough) when taking it from the mold. So you put it through your planer, bottom side down, to plane the top and get that flat, then flip over to get rid of excess resin etc.

I've seen people seal the bottom of the board opens with hot glue have you seen that and what your thoughts. To prevent leaking

I have never seen it done with hot glue. Also, you definitely don't want to use hot glue in a silicone mold. It would be ok to use in an HDPE or tuck tape "homemade" mold though.

Shawn, is it really necessary to buy a finishing sander? Why can't I use my dewalt orbital sander that is NOT a finishing sander? What is the purpose of a finishing sander? Will a regular sander work on river tables? I'm sooooo confused? Can you help?

Cliff. I use a Dewalt orbital sander. I dont use a finish sander.

What total boat epoxy product is recommended for 18x6.5x1" Cheese Board With Organic Handle?

The Total Boat Thickset (not fathom... though that would work too)

Love!!

What safety gear do U wear so ur not having toxic fumes in ur eyes nose ?? Filter/goggles?

I normally wear a P95 or P100 respirator from 3M. Goggles are something I usually avoid.

What is the name of the stuff you put on the molds before pouring the epoxy?

Mold release? We use MG Chemicals 8329

do you have a 13 1/2" x 35 1/2" rectangular shape silicone mold?

All of our rectangular molds are here: craftedelements.com/collections/rectangle-molds

How do you charge for a board that size? Does the walrus oil have to be re-applied ?

Possibly $140-$180

The exposure material you used, are they food safe? And what do you seal the top layer of wood with to prevent food stains or drink rings? Many thanks!

Exposure? I dont quite understand. However, we generally use TotalBoat Wood Honey, Walrus Oil or food grade mineral oil to seal and oil the boards.

@@CraftedElements it was autocorrect, 🥸, but you understood enough to answer. 😂 Thank you for your reply. 😀

@@shannonmac7801 No problem at all! Be well.

I see that you use weights to keep the resin from leaking. How much weight do you place on the boards when using one of your cutting board molds? I just bought the mold from you . I always have trouble with leakage when using my wooden molds and am hopeful with your advice, I can get this right. Thanks.

We use 8lb handweights, or 15/20lb kettle bells. Common workout weights basically. Usually put an HDPE block in between the wood and the weight to prevent the weight from sticking to the wood if resin spills over -> craftedelements.com/collections/new/products/hdpe-hold-down-block-kit-for-silicone-molds

What sizes do the molds come in?

We have nearly 50 sizes as of today, so you should check CraftedElements.com to see if there is an ideal size for you.

How much would the epoxy for this project cost?

Rusty is in Burlington :-)

Indeed they are!

Love It! One question, the live edge is in. What the point in draw knifing it off when that the look you go for? Could you just nail the bark on there with a finish nail?

Again Love your projects! Can’t wait to try this board! 🤝

No, the bark always needs removed. The epoxy will bond to the bark and it will eventually just break off from the wood (as bark usually does).

@@CraftedElements Ohh ok. You would think with it being incased in Epoxy that it wouldn’t do that. As if the epoxy holds everything together. That’s just my logical thinking. Lol. I’ve never done epoxy work. But I am willing and eager to try this. I love how you give perfect directions and instructions like we as fans are there with you. It helps so much for people like me who are apprehensive or nervous on trying something new. So I Thank You. I should be receiving my 3 Templates I ordered from you sometime today. So Thanks for that! Have A Great Day Sir. And keep the videos coming! 🤝

@@jamesbarlowjr.3762 Totally makes sense! seems logical that nails would hold the bark in place, but no, sadly it wont. Plus, bark is pretty moist and low density, not something you want on a cutting or serving board coming into contact with food. Thanks for watching!

@@CraftedElements Ohh ok. Thanks for the responses I really appreciate it. I’m just learning. So please don’t mind the silly questions. Thanks Again! 🤝

Where do you get the wood from ?

You can get wood from local lumber suppliers (check google). You can also find wood from Craigslist, FB marketplace etc. Just make sure its kiln dried!

What was the cost of that board and What would you retail it at ? Also do you make car freshly molds?

Likely around $180 USD for something that size.... car freshly molds (: puzzled)

Does the oil go down into the resin?

Resin would be impervious as its plastic. But it will fill the microvoids in the top layer of the resin, making it "shine".

What species of wood are you using?

I believe in that video it was ambrosia maple, or wormy maple. Hard to tell and it was a while ago!

Is the resin in the boards food safe?

There are many food safe resins, yes. Just be mindful that most resin is BPA based, so although FDA food safe, its not REALLY super safe.

If I wasn't using it for food, what type of oil or finish would I apply on top?

This might help: th-cam.com/video/OzXFmnUy4rY/w-d-xo.html

Is the Epoxy ok to set food on? Thanks

It is. But don't cut on it, you will damage the epoxy/leave a mark.

@@CraftedElements Ok. Thanks for responding. Appreciate You! 🤝

Is resin in the boards food safe?

Generally there are more food safe resins than others, but many resins are BPA based. Which is "food safe", but clearly not ideal for the interior of aluminum cans.

Hi Mate, can you use epoxy rsin for cutting boards. I have read and heard that you shouldn't, what do you recammend regards Gary from Australia

You could use resin to fill in voids in a cutting board, but ideally its just not functional for a cutting board. When you use a sharp knife in resin (which is plastic) its going to scar it and with multiple cuts overtime its just not going to look good.

@@CraftedElements thank you for the feed back appriated, I love your educational youtube for someone that about to do epoxy it is a great learning curve

@@garysevior8602 You are welcome!

Can you hot glue the wood down so it doesn’t float in a silicone mold?

No, not with a silicone mold.

@@CraftedElements Ty is weighing down the wood the best method or would you recommend another method for preventing wood from floating in silicone molds?

@@Tyno913Yes, using handweights is easiest. Otherwise, using clamps (keeping the mold near the edge of your table and clamping between the bottom of the table and your wood)

You dont pop the grain?

A completely Unrelated comment but when you use those gloves have you ever seen heard of or tried the cotton glove liners or the cotton inspection glove some call them. In my personal opinion I look at it like the inspection gloves are a little thicker and the cotton glove liners are thinner but the thinner ones are amazing to use under the nitrile gloves and the combination is still thin enough that you can handle small pieces and parts and what not

I'm a bit lost. But thank you for the suggestion.

I just bought my first two molds from you guys and got a card with a big warning. 1. don't put your torch on the mold (which the guy in the video brags about being able to do) 2. use a non-silicone release agent (which the guy in the video says no release agent needed, just put the wood in and go). Which is correct and why the two voices from one company? Just preference? I am new...

Dont use a torch on the mold, unless you are briskly waving it to pop bubbles. Silicone can only handle up to 450F. Use a mold release -> craftedelements.com/moldrelease

Why did you trim your pieces on the tablesaw?

A silly question,,I take it you can cut on the board without damage to the epoxy resin to much,,🤔🏴🤔🏴

Cutting directly on resin with a sharp knife will leave a knife mark in the resin. These are mostly serving boards, NOT cutting boards. A strict cutting board should be mostly hardwood.

😯😯😯😯😯

i wanted one of your molds but $150usd +shipping to Aus is out of my range , any tips on a DIY version of the silicon mold ?

So, a DIY silicone mold would cost much more than one of our molds because of the initial tooling involved. To create proper tooling, out of aluminum or acrylic, to make the shape of the mold, you are looking at $500 for something small, $10K+ for something large. You could do a really rough form with wood or plastic, seal it and then buy some RTV silicone and pour it in, but I guarantee it wont be any cheaper in the long run.

@@CraftedElements cheers for the reply , i think i found some cheaper methods to start with for small scale. if it turns into something i enjoy i'll look at investing in something that im sure makes life 100 times easier :)

What are the health consequenses of resin powder on food caused by constant cutting ?, its been reported that resin shards have been found on food after use.

Generally we recommend resin for serving / charcuterie boards and not for creating full cutting boards. Resin is ok to fill small voids or pits in a cutting board, but yes, if you cut on resin it has a chance of getting scared.

Couldn’t you use art resign and just pour a little wait an hour then another layer etc?

Yes, you can layer resins that are designed for shallow pours (or art). We occasionally do this. The issue is 1. It takes time, 2. If you are coloring it, the pigmentation is usually off and you can see the layers from the side, 3. Even a layered clear pour is usually distinguishable from the side view. But... YES.... it will work.

I wonder if you sell more molds than boards, etc. Thanks for the video

Yes we do. Definitely.