Direct PCB Printing with a Modified Laser Printer

ฝัง

- เผยแพร่เมื่อ 22 ส.ค. 2015

- These days I am using www.banggood.com/custlink/KvD...

to expose circuit boards!

www.instructables.com/id/Modif...

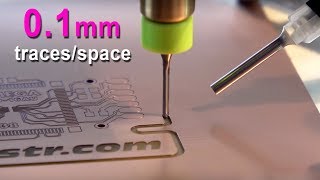

With a modified Lexmark E260 Laser Printer you can directly print on copper clad boards! There are some difficulties but for small single sided boards it works fantastically!

Hello,

probably I have an explanation why you have to stretch PCB "image".

You do not take in account that when you feed PCB board through the printer, it pulled by rubber rollers.

As your board is significantly thicker than sheet of paper the rubber roller is compressed more than it was designed for. The compression of rubber "decreases diameter of rubber roller and circumvent of roller decreases" -- the PCB board feeds at slightly slower linear speed than it should.

Electronics of the printer control angular speed of rotation the rubber roller and was not designed to use thicker print media. If you could increase spacing between rollers to maintain original pressure then linear speed should be correct and printed image would not require a "correction" by adding 1% in direction of movement.

+John Dreamer Thats a solid explanation, thank you so much! I also noticed that the distortion disappears when printing on thin media.

long live the S-S-S-S-S-even segment display clocks :)

Pro tip from someone covered in this toner for years: I recommend you keep the foam from the toner cartridge. NOTHING cleans up toner better than that foam.

Such a relaxing voice. Watched it twice just for the Asmr

I recall watching this a couple of years ago when interested in PCB building at home. One of your coolest projects.

Everyone screamed NOOOOOOOO when you rubbed your finger on the board and smeared it. But a great demostration, and the acetone trick is awesome, like yourself. We are big fans of your work and teachings.

mate, your projects are amazing!

Thanks Professor Snape!

Great video. I really like your method. (I only came across your video now and see it was already posted approx 3 years ago ) I use the Photoresist method (Positive 20) with various odd tricks & am happy with my results. I appreciate how much work it took to convert your printer. I hope by now you have solved the problem of the damage to the photoconductor roll.

well done. it has crossed my mind to try this with a suitable printer, but i was worried it will damage the drum.

As you're working on bare feet just touch PCB with finger while printing to get a GOOD ground connection. Mains and bare feet is always a deadly combination! 😇

you can shake some powder coat on top of the laser toner,blow out the surplus, and then put it in the oven. It will give you a nice thick surface for protection and it will keep the dimensions of the toner

Just heating printed PCB with an iron or with a soldering fan works well without the acetone.

Very good work... No need to use acitone.. apply heat.. in toster oven

I am agree, just apply heat.

Thank you very very much for your display

Uow, 2022 and it's still an interesting video.

The extra aluminum or steel rollers were probably to level guide the PCB. Unfortunately those toner cartridges are so sensitive, and expensive. Good work - figuring out the ground! I did this trick years ago, it didn't work for me - but if I knew about the grounding it would probably have made a big difference. I had to stop trying when I figured out the PCB'S were so inconsistent it never seemed to get a good print for me.

If you pre-heat your board, maybe add one of those 3d-printer heating elements to the bottom, as it rolls through - at just the right temprature would be enough to cure the toner to the surface. Also, they can go in a toaster oven, instead of using acrylite to fuse the surface.

Thank you Erich. That is really helpful and makes a lot of sense. Those virgen PCB's are not consistent. They are wavey and are hard to lay flat, and are not square either. What you wrote about that is the main cause of the problem with this method was revealing and helpful, so I don't go down the wrong road. THANK YOU ERICH!!!!

Hello ! Thank you for your videos ! Can I use Lexmark E460 in this project ? May be you know ? I have new e460, but can not find good price for e260...

Thank you so much for this video, and your others too for that matter, but this video helps me decide which way to go and I am moving toward the idea of a CNC that will using a black marker pen to draw out the copper traces. Then etch, and then put back into the exact same CNC machine for drilling. The CNC will have tool offsets for the black marker pen and the drill. I suppose it is more desireable to etch first before drilling to save on drill bits and to make drilling faster. My CNC design would have an easy way to set the PCB board on the tray bed, like an "L" shaped corner where you can set the PCB in the corner of the "L" and push it into the corner tightly and then use some kind of method to hold it in there. Then you could just draw the PCB, etch it, and then drill with no worries of mis-alignment.

Have you tried transparency film and photoetching? Or direct laser imaging onto photoresist (like a laser projector imaging the photoresist coated PCB) ?

I wonder if you could round over the edges of the PCB with a file or sander to prevent scoring the roller?

Great video, I use the old iron on method with the iron set to medium. Before I start to iron I spray some silicone spay on a rage , then I iron the rag to transfer the silicone onto the iron. this makes the iron very slippery and prevents smudging. I have used this method for years and seems to work very well.

Love you channel!

Rearranging printer roller with Alumina rollers is a good way but chromium rollers work best for dyes and also engraved PCB works very effective rather than the emboss PCB. The printer looks good though.

the main disadvantage is the additional time for binding with the acetone, what is you main problem with the toner transfer method?

I mean printing on paper and transfer to the metal isusually takes less than 1-2 minutes.

I figured out when i started that my toner does not work with isoalcohol, and acetone disolves to fast (1-5 sec) so its unusable (even mixed with iso). Through experiments i found a better solvent: Xylene sold in Germany as "Universal Paint Thinner or Nitrothinner".

Tro be sure look on the ingredients of the can.

I found out that for my toner the best mixture is 75% isoalcohol +25 Xylene.

Its because there is enough Solvent (Xylene) and enough time to work with (doesnt evaporate instantly like with the actone i tried).

Ah , there is one caviar, instead of normal paper i have to use magazine paper (doesn't matter if it has already color on it.) i use the Paper from the IKEA Kataloge i got for free :).

Main reason i took that experimenting hassle is i wanted to elektro-etch a logo on a knife.

Does it have to be laser printer? As we no longer need to transfer layout to board we could use DTG printer.

Check your printing in precession 3 digits in gerber plots output settings,I assume your using MM Metric outputs from plots?

Just a thought.

sorry didnt realize the upload date but here goes...this application much better than photo resist film however I am just beginning. may I ask what kind of etchant you are using? my recent purchase from eBay - a white crystalline with no name. can't figure out its chemical nomenclature. mixed messages about ratio as well. I can always go to ferric chloride but wanted a tidier option

Chris , by now you have probably sorted yourself out re etchant. An alternative to Ferric Chloride is Copper Chloride in aqueous Hydrochloric acid solution - will need HCL and Hydrogen Peroxide , the HCL easily available as Pool acid and the H2o2 available at chemists (drugstores) needles to say , goggles, gloves are imperative and don't breath the fumes ;-) Check out TH-cam's NurdRage for a good explanation on a good number of alternative etchants which is where I got the one above

Marco, thanks for perfect howto on your instructables page.. I found your UPDATE recently, are you happy with 2.5W laser way of preparing pcb's ? I suppose that you are using that machine just for masking copper or are you able to engrave copper layer totally ?

I am editing the video about the laser machine right now, should be up tomorrow! Yes it is a masking technique! Otherwise it would either leave molten/oxidized copper behind, or it would have to vaporize it :)

Cool, I look forward to it.. I have bought old Lexmark but this way looks more straightforward and cheaper if I take into account my time

How EleksMaker® EleksLaser-A3 Pro 2500mW Laser Engraving Machine CNC Laser Printer works? Could you explain please.

Hello Marco you can help me with my problem, unfortunately the fact that the printer does not recognize the toner cartridge stops me totally.

Thank you very much.

I have had nothing but good luck with toner transfer.

If youre trying to build doublesided PCB, why dont you use two really thin one layer PCBs and epoxi them together?

+NeumiElektronik It would be hard to perfectly align the two layers.

+Kevin Gutknecht Drill some alignment holes (i.e. 1mm) then put some 1mm wire in it. Should be enough to align the sides.

exactly

Print layers on thin( 10mil or 15mill ) single sided stock.

Not at all hard to do. After etch, drill out some holes and vias, use pins or lancet needles to align use 5min or longer epoxy. press boards and pins into stiff foam with wax paper. Done

It would be difficult to make plated vias, which is the point of two sided boards

I think I have one of these exact same printers. I just need to get a new toner cartridge for it.

With all these downsides, I just don't see the benefit over laser printing on tracing paper, applying a bit of oil and exposing the board. This works great for me and I find the exposing the most relaxing part of the process, while the etching takes most time, preparation and cleanup. Also Acetone and Toner dust are are recepie for cancer.

do you have a video? i didnt know you can use oil as transfer medium.

Acetone is not cancerous just unhealthy like glue sniffing. Its a simple chemical.

The toner is ,since most dust partcles are a serious health danger and cancerous.

your straight crazy bro! wow. very intelligent

well if you have to wait half an our for the toner to get hard, i think you might aswell use an iron. personally i'm just thinking of getting a small flocking heat transfer press for transfers

So this is just a regular office printer and its normal toner cartridge?

cool all i need is a modified laser printer. thanks a whole lot.

It says "modified laser printer" in the title…

Get extremely thin PCB material.

That will stop the damage to the drum and conform to the flatness of the drum.

You can then make as many layers as you like, stack them and plate the holes.

AFAIK, plating holes at home is a no-go. It's a very complex process.

Why the Acetone method? If a regular laser printer uses heat to fuse the toner, and the regular fuser isn't strong enough, what about a small kitchen-top pizza oven, or a reflow oven (which, in hobbyist circles tend to be the same, really :p)?

I wondered the same thing but maybe heating the toner that way makes it run, or something?

Your voice reminds me of professor Snape for some reason

how did you modify your printer???

Amazing!!!!

Toner Transfer ist much easier. No need to modify printer, just a suitable catalog page and a laminator. Works down to .2mm no problems.

Hmm, I have a couple laser printers laying around. It might be worth a try.

Marco, some pyralux stuff experiments needed!!!1

Good idea sir. Hardware Changes video share please Thank you 🙏

4 layer 2oz 0.1mm tracks have ruined me.

Absolutely stopped taking pain for star grounding, snaking traces. Cheap 4 layer PCB goes brrrrrr

Very nice ... cool

Super , new information

Why you dont use photo paper with hot iron

Does anybody remember the CD/dvd printers that we had 15 years ago? You'd put a CD in the tray, and a solid pigment image would adhere to the surface. A little surprised we can't hardness that for printing boards directly.

I guess...

It's LightScribe optical drive , what you pointing out right ??

@@omsingharjit They were inkjets.

Hello, I'm thinking about a fancy way to avoid the acetone part.. What if you use the pcb copper layer as a resistor, applying some current to it, in order to make it warm and dry the ink?

It's a nice project, I think that with some tuning you will achieve a correct result.

Probably if the printer firmware was open source, then with some modifications, and adding more sensors would result in a perfect print on the pcb.

Maybe you can add some rollers at least to protect the toner from those scratches... They don't look very good!

I don't know the laser print process, but maybe is not the most indicated... Think about an inkjet, modified to use a thicker ink, more like paint, that will dry in minutes... I think that it will be less sensible than laser.

I have seen printers modified, in order to be used with clothing, is not an unusual thing.. Maybe some printers are more indicated, or have a firmware that it's more suitable than the others!

How i can get one

great

What??? You didn't make a cnc machine to just route out the .001mm copper? just kidding, this is awesome,

I was thinking exactly this after dozens of failures of toner xfer, why can't I just print right to the copper??

I haven't taken apart a printer, but I assumed the paper must roll past the laser curved around, so a solid sheet would not work,

is that why you must strench the image? ok this was 6 years ago, you have made the cnc machine now right? :)

there is a better method. I use A4 Paper with a gum coating (like post stamp). Then i print on the gum side and transfer with a modified laminator. solved all the problems you mentioned. also double side no problem and no changes on printer needed. only put into water and the paper come off with no force.

circuit on pcb : )

what type of ink chemical it used. acetone can melt any type of ink. how is it possible?

danilo suarez It's not ink; it's toner.

كنت اتمنى انهاء المشروع بشكل كامل

Hello, is possible to make this modification in a lexmark E360?

+Daniel Luis Franco I wondered about that, too. Because several E360 ones were available even cheaper. But I didn't try it. Please let us know if you do! I think the chances are good.

I purcharsed a E360 and I will try to do, I think it will work, apparently the difference is only the display in E360.

Hello ! Waht about your experiments with e360 Lexmark ? I have e460, what you think about using e460 in this project ?

One year later... were you successful?

i think the sketch is not good because the mfps is not working at all but it works without mcu mod. the sketch was compiled and succesfully written on the atmega328 mcu but i had no luck i guess with mcu mod.

Cristi, afinal de contas, sua impressora Lexmark E260, funcionou na impressão de placas ? Ela ainda funciona até hoje ?

try using double sided tape to keep the boards flat on your carrier plate.

why not a jetink printer Instead of a laser tonner printer? the ink of jet printers is not good for the etching

Walking in lab barefoot... I find that... Disturbing.

But, all the rest, nice vid. I did the similar thing some time ago.

I'm with you bro. Safety today, or sorrow tomorrow.

you'll learn to keep your ICs stored :D

Long shot but can you try this with a more recent and easy to obtain printer like a brother HL-L2360DW?

wow

I vote for heatgun :)

👍👍👍👍

Stop, don't go back any further than this, awkward zone ahead!

Just print it on paper and then transfer to pcb with an iron

hmmm - registration shouldn't be a HUGE problem

ssssss seven segment

Are you from Germany ?

I am guessing.... !!

Ooh you have already told he here around 7:59

It was because your way of talking is similar to great scoot

Can you share the .hex and schematic for atmega328?

+cristi eu here is an unrefines arduino sketch if that helps you: gotta dig a little deeper for other things

const int sw = 2;

const int npis = 3;

const int mfps = 9;

const int es = 10;

const int pis = 12;

const int led = 13;

void setup() {

pinMode(sw, INPUT);

pinMode(npis, INPUT_PULLUP);

pinMode(mfps, OUTPUT);

pinMode(es, OUTPUT);

pinMode(pis, OUTPUT);

pinMode(led, OUTPUT);

digitalWrite(mfps, HIGH);

digitalWrite(es, HIGH);

digitalWrite(pis, HIGH);

digitalWrite(led, HIGH);

}

void loop() {

if(digitalRead(sw)==LOW) {

step1();

}

}

void step1() {

digitalWrite(led, LOW);

delay(1000);

digitalWrite(mfps, LOW);

while(digitalRead(npis)==HIGH){

}

step2();

}

void step2() {

digitalWrite(led, HIGH);

digitalWrite(pis, LOW);

delay(1825);

digitalWrite(es, LOW);

delay(950);

digitalWrite(mfps, HIGH);

delay(825);

digitalWrite(pis, HIGH);

delay(1875);

digitalWrite(es, HIGH);

}

+Marco Reps i will try today with atmega328, thanks.

Overall Making affort will be the same

Nice. But also very noble, since you can order super nicely made pcb's for $5-10. Yes that will take 2 weeks. But that's easy to take into the planning.

Time is money when you're prototyping.

Seriously :o

After 17 years as a photocopier technician, I never knew that acetone vapours would fix toner.

As for the alignment, the rollers are designed to feed the paper just a bit cause a slight buckle in the paper, forcing the paper the be straight across the first set of rollers.

Since you cannot buckle the copper clad board you cannot ensure that it is evenly aligned every time.

Aluminium

Why not use a toaster oven or similar set to 200ºC to fuse the toner instead of carcinogenic chemicals? Laser printer fusers run at about 200ºC.

Acetone has been studied extensively and is generally recognized to have low acute and chronic toxicity if ingested and/or inhaled. Acetone is not currently regarded as a carcinogen, a mutagenic chemical or a concern for chronic neurotoxicity effects.

I guess I have the same idea but to preheat the copper board before running it thru the printer. Just a thought .....

Are you sleepe?

Can't see (in the 30 seconds I gave it) any mention that toner powder is, apparently, carcinogenic - so take care with it in your environment before it is fused..

nice feet

Sssssssssssssseven segment display clock

hello anyone here...?

:D

0:30 Cant be more obvios Mr. Reptilian?

ipasuhd Ssssssssssss

Just give me a call please

why not just cook it in hoven: 10 minutes at 200 and toner is set for ever: I print my face plate that way ! And no funky smell of awfull acetone

Jose Sanchez A heat gun might be even faster

@@powder-phun949 it might blow the toner dust

it also needs slight pressure or an the way the printer is designed with was using eletrostatic charge

BIG FAT WARNING! I just read the instructable and it recommended a shop vacuum for cleaning up toner dust.

NEVER do this unless you are sure that the vacuum has an anti-static hose.

I once witnessed a colleague blowing his office windows out with a toner dust explosion after using an ordinary vacuum to clean a laser printer. Fragments of glass and plastic were embedded in the ceiling tiles and he came within an inch of losing an eye.

what should I clean my laser printer with?

@@zoltanbiro6388 You can get get special anti-static vacuums. Normals vacuums have nylon tubes which can cause sparks as the dust passes through them

this is a comment.

Use photo paper and print...thats the best and easy way....

Alter der redet englisch wie ein deutscher wurstwassertrinker

Dein Deutsch ist auch nicht viel besser.

another cool video but why are you speaking so slowly? if its because of critism for speaking too fast before, then.. well youve gone too far in the other direction i have to say ^^

Play at 1.25x...thank me later

*Yet Another YT Joker!*

i disliked this video because you talk slow and sad if you keep doing it i will unsuscribe too

All printers reduce images by 1% or 2% to thwart printing of counterfiet money. Automatic paper money counters detect tis slight difference to detect fake money.

That does not make sense. Where in the world have you heard that?

hpekristiansen GOOGLE it! There is tons of information, and yes, it is designed to not make sense.

There are no information about it, because it is not true.

is that why when i print something that is exactly 180mm x 150mm it comes at exactly 180mm x 150mm?

Oh yes, the lady at the check-out would surely notice counterfeit money from being ONE PERCENT SHORTER than real money, as opposed to having a particular feel, UV markings, and other features that are not only much more difficult to fake but also much easier to verify. Yep, the correct length will surely be the very first indicator she will check for, and notice, your attempt at paying with fake money. And automatic counting machines will surely and unerringly be able to tell fake from real money by measuring the length which is totally not subject to vary due to wear and tear around the edges. Yes. That's exactly it. Well done figuring that out. Here, I award you this Hat of Recognition-of-the-Most-Retarded-Comment-on-TH-cam-of-the-Year-or-At-Least-until-I-find-the-Next-One-that-is-Even-More-Retarded-on-Another-Video-although-You-have-set-The-Bar-quite-high-for-any-Contenders-There-so-That-could-get-Difficult. Congratulations.